If you haul freight regularly, you’ve likely dealt with crushed corners, torn straps, or damaged cargo. Many shippers and drivers search Corner Protectors For Truck Loads because even well-secured loads can shift, rub, or fail under tension. Corner protectors are a simple, low-cost solution that dramatically improves load safety, reduces claims, and extends the life of your tie-down equipment.

What Are Corner Protectors for Truck Loads?

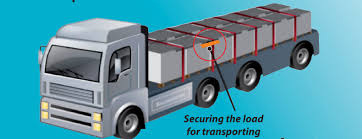

Corner protectors for truck loads are rigid or semi-rigid devices placed on the edges and corners of cargo. Their primary purpose is to distribute strap tension evenly and prevent direct contact between tie-down straps and sharp cargo edges.

Read too: Top Trucking Companies That Still Have Manual Transmissions

In simple terms, they:

- Protect cargo corners from crushing

- Prevent straps from cutting into loads

- Improve load stability during transport

- Help meet cargo securement standards

They’re widely used in flatbed trucking, LTL freight, construction hauling, and palletized shipping.

Why Are Corner Protectors So Important in Trucking?

Cargo damage doesn’t just cost money—it affects safety and compliance.

Key Problems Corner Protectors Solve

- Strap abrasion and premature failure

- Load shifting during braking or turns

- Crushed cartons or bent materials

- Rejected deliveries and insurance claims

Industry freight studies estimate that over 25% of load damage incidents involve edge or corner stress, not strap failure alone.

How Corner Protectors Work (Step-by-Step)

Understanding how they function helps you use them correctly.

Load Securement Process

- Cargo is positioned on the trailer or pallet

- Corner protectors are placed on all exposed edges

- Straps or chains are routed over the protectors

- Tension is applied evenly

- Force is distributed across a wider surface

This reduces pressure points that normally cause crushing or cutting.

Types of Corner Protectors for Truck Loads

Not all corner protectors are the same. Choosing the right type matters.

1. Plastic Corner Protectors

Best for: Palletized goods, boxed freight

Pros

- Lightweight

- Affordable

- Resistant to moisture

Cons

- Limited load capacity for heavy steel or lumber

2. Rubber Corner Protectors

Best for: Delicate or finished surfaces

Pros

- High grip

- Shock absorption

- Reduces slippage

Cons

- Heavier than plastic

- Slightly higher cost

3. Steel or Metal Corner Protectors

Best for: Lumber, steel coils, concrete products

Pros

- Extremely durable

- Handles high strap tension

Cons

- Heavy

- Can damage soft cargo if misused

4. Composite or Reinforced Corner Protectors

Best for: Mixed loads

Pros

- Balanced strength and weight

- Long service life

Cons

- Higher upfront cost

Which Loads Require Corner Protectors?

While not always legally required, they’re strongly recommended in many cases.

Loads That Benefit Most

- Palletized freight

- Lumber and drywall

- Steel beams or pipes

- Appliances and machinery

- Furniture and boxed goods

If a load has sharp edges or fragile corners, corner protectors should be considered mandatory.

Corner Protectors vs No Protection (Comparison)

| Factor | With Corner Protectors | Without Protection |

|---|---|---|

| Strap lifespan | Longer | Shortened |

| Load damage risk | Low | High |

| Strap tension control | Even | Uneven |

| DOT compliance | Easier | Risky |

| Delivery acceptance | Higher | Lower |

Do Corner Protectors Help With DOT Compliance?

Yes—indirectly but significantly.

While U.S. DOT rules focus on securement performance, corner protectors help prevent:

- Strap cutting

- Load movement

- Securement failure

This supports compliance with cargo securement standards enforced during roadside inspections.

How Many Corner Protectors Should You Use?

This depends on load shape and size.

General Rule of Thumb

- One protector per exposed corner per strap

- For pallets: minimum 4 corner protectors

- For long loads: additional protectors where straps cross edges

More protection is always safer than less.

Step-by-Step: How to Use Corner Protectors Correctly

Improper use reduces effectiveness.

Correct Installation

- Inspect the cargo for sharp edges

- Place protectors firmly on corners

- Align strap channels (if present)

- Apply straps evenly

- Tighten gradually

- Recheck tension after 10–15 miles

📏 Tip: Maintain even strap angles to avoid side loading.

Common Mistakes Truckers Make

Avoid these costly errors:

- Using protectors that are too small

- Skipping protectors on “short” trips

- Misaligning strap channels

- Reusing cracked or damaged protectors

A damaged protector should be replaced immediately.

How Corner Protectors Reduce Costs Over Time

They may seem like a minor expense, but they deliver real ROI.

Cost-Saving Benefits

- Fewer rejected deliveries

- Reduced strap replacement

- Lower insurance claims

- Improved customer satisfaction

Many fleet operators report 10–20% lower cargo damage costs after consistent use.

Corner Protectors for Different Industries

Different loads require different approaches.

Construction Materials

- Heavy-duty plastic or steel

- Wide load-bearing surfaces

Retail & Consumer Goods

- Lightweight plastic or rubber

- Smooth, non-marking edges

Industrial Equipment

- Reinforced composite protectors

- Multiple protectors per edge

Environmental and Reusability Considerations

Most modern corner protectors are reusable and recyclable.

- Plastic models often last years

- Rubber versions resist weathering

- Composite protectors balance durability and sustainability

For general background on freight handling and cargo transport concepts, you can reference:

https://en.wikipedia.org/wiki/Freight_transport

(This link is provided for general educational context only.)

Are Corner Protectors Required by Law?

They’re not explicitly required in all cases, but failure to protect sharp edges can lead to violations if straps are damaged or loads shift.

Best Practice

If a load edge can damage a strap, protection should be used.

Choosing the Right Corner Protectors (Quick Guide)

| Load Type | Recommended Protector |

|---|---|

| Cardboard boxes | Plastic |

| Furniture | Rubber |

| Lumber | Reinforced plastic |

| Steel | Metal or composite |

| Mixed freight | Composite |

FAQ: Corner Protectors For Truck Loads

Frequently Asked Questions

Q1: Are corner protectors reusable?

A: Yes. Most are reusable unless cracked or severely worn.

Q2: Do corner protectors prevent straps from breaking?

A: They greatly reduce strap abrasion, which is a leading cause of failure.

Q3: Can I use corner protectors with chains?

A: Yes, especially on sharp edges or finished surfaces.

Q4: Are plastic corner protectors strong enough?

A: Yes, for palletized and light-to-medium loads.

Q5: How often should I inspect corner protectors?

A: Before every load to ensure no cracks or deformation.

Conclusion: Small Tool, Big Protection

Corner Protectors For Truck Loads are one of the simplest and most effective ways to protect cargo, improve safety, and reduce operating costs. By distributing strap tension and shielding vulnerable edges, they prevent damage that could otherwise lead to delays, claims, or violations.

If this guide helped you understand how to protect your loads more effectively, share it on social media so other drivers and shippers can haul safer too.

Leave a Reply