In industrial environments, efficiency, reliability, and safety are critical for material handling. One key component that contributes to these factors in overhead crane systems is the End Trucks For Bridge Cranes. These components play a pivotal role in the movement and stability of bridge cranes, which are essential in factories, warehouses, and heavy-duty industrial facilities.

An End Truck For Bridge Cranes is designed to support the bridge crane and enable smooth travel along runway rails. Understanding their design, function, and maintenance can help plant managers and engineers optimize crane performance and ensure safe operations. This article provides a comprehensive overview of End Trucks For Bridge Cranes, their types, benefits, and practical applications.

What are End Trucks For Bridge Cranes?

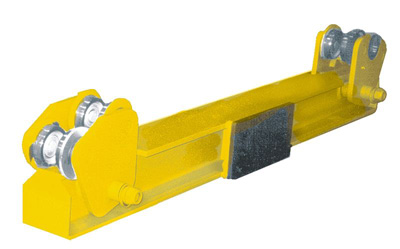

End Trucks For Bridge Cranes are structural assemblies located at each end of the crane bridge. They house the wheels or trolleys that allow the bridge to travel along the runway beams. Essentially, they act as the interface between the crane bridge and the supporting rails, distributing the load and ensuring smooth movement.

Read too: Franklin Truck Parts Near Me: Your Complete Guide to Local Truck Parts & Repair Solutions

Key components of an end truck include:

- Wheels: Often made of steel or polyurethane, designed to roll along runway rails.

- Axles and Bearings: Provide smooth rotation and support heavy loads.

- Frames: Structural framework connecting the crane bridge to the wheels.

- Motors (in powered models): Drive the crane along the runway.

End trucks are crucial for the stability, safety, and performance of bridge cranes. Without properly functioning end trucks, a crane cannot move efficiently, which can lead to operational delays or safety hazards.

Advantages of Using End Trucks For Bridge Cranes

1. Smooth and Efficient Movement

One of the primary benefits of End Trucks For Bridge Cranes is their ability to provide smooth, controlled movement along the runway. Well-engineered end trucks minimize friction and vibration, which is essential for handling heavy loads safely.

2. Load Distribution

End trucks help distribute the crane’s weight across multiple wheels and axles, reducing stress on the runway rails and enhancing the crane’s longevity. This load distribution ensures stability, even when transporting extremely heavy materials.

3. Improved Safety

Safety is a top priority in industrial operations. End trucks reduce the risk of derailment and uneven movement, which can cause accidents or damage to goods and equipment. Many modern end trucks are equipped with advanced braking systems to enhance operational safety further.

4. Versatility

End trucks are available in a wide range of configurations to accommodate different types of bridge cranes, including single girder and double girder cranes. Some end trucks are designed for high-speed travel, while others are optimized for heavy-duty lifting applications.

5. Reduced Maintenance Costs

High-quality end trucks are engineered to endure continuous operation with minimal maintenance. Features such as precision bearings, durable wheels, and robust frames reduce wear and tear, saving businesses money on repairs and downtime.

Types of End Trucks For Bridge Cranes

Choosing the right type of end truck depends on the crane design, load capacity, and operational requirements. The most common types include:

- Single Girder End Trucks

- Designed for single girder bridge cranes.

- Typically lightweight and cost-effective.

- Suitable for moderate load capacities.

- Double Girder End Trucks

- Used with double girder cranes to handle heavier loads.

- Provide superior stability and durability.

- Ideal for industrial applications requiring high lifting capacity.

- Motorized End Trucks

- Equipped with electric motors for powered crane travel.

- Provide precise control over speed and movement.

- Reduce manual effort and improve operational efficiency.

- Adjustable End Trucks

- Feature adjustable wheel spacing to accommodate different rail widths.

- Increase flexibility and ease of installation.

Key Features to Consider When Selecting End Trucks For Bridge Cranes

When selecting End Trucks For Bridge Cranes, it is essential to consider the following factors:

- Load Capacity: Ensure the end trucks can support the crane and maximum load safely.

- Wheel Material: Steel wheels offer durability for heavy loads, while polyurethane wheels reduce noise and wear.

- Frame Strength: The frame should be rigid enough to handle stress and prevent deflection.

- Operational Speed: High-speed end trucks require precise engineering to ensure stability at elevated speeds.

- Maintenance Requirements: Choose designs that minimize downtime and are easy to service.

- Compatibility: Ensure the end trucks are compatible with the crane bridge design and runway specifications.

Applications of End Trucks For Bridge Cranes

End Trucks For Bridge Cranes are widely used in industries where overhead material handling is essential. Some common applications include:

- Manufacturing Plants: Transport heavy raw materials, components, and finished products across production lines.

- Warehouses and Logistics Centers: Move bulk materials efficiently while minimizing manual handling.

- Shipyards: Assist in lifting and positioning large ship components.

- Steel Mills and Foundries: Handle molten metals, heavy steel plates, and industrial machinery safely.

- Construction Sites: Facilitate the movement of prefabricated structures and construction materials.

In all these applications, end trucks are vital for ensuring smooth crane operation and maintaining high productivity.

Maintenance Tips for End Trucks For Bridge Cranes

Proper maintenance is critical to extend the life of End Trucks For Bridge Cranes and ensure safe operation:

- Regular Inspection: Check wheels, axles, and bearings for wear and damage.

- Lubrication: Keep bearings and moving parts properly lubricated to reduce friction.

- Wheel Alignment: Ensure wheels are aligned to prevent uneven wear and improve movement efficiency.

- Cleaning: Remove debris and dust that can interfere with wheel rotation.

- Professional Servicing: Schedule routine inspections by qualified technicians to maintain safety standards.

Adhering to these maintenance practices can prevent costly breakdowns and downtime.

Benefits of Upgrading to Modern End Trucks For Bridge Cranes

Modern end trucks incorporate advanced materials, precision engineering, and innovative features that improve crane performance:

- Increased Load Capacity: High-strength materials allow for lifting heavier loads.

- Enhanced Safety Features: Integrated braking systems and load sensors reduce accident risk.

- Energy Efficiency: Motorized end trucks with efficient drives reduce power consumption.

- Longevity: Durable components extend service life, reducing replacement costs.

Investing in modern end trucks ensures reliable crane operation and improved productivity across industrial applications.

Conclusion

End Trucks For Bridge Cranes are fundamental components that directly impact the efficiency, safety, and longevity of bridge crane systems. From load distribution to smooth travel and versatile applications, end trucks enable industries to operate more efficiently and safely.

Selecting the right end trucks, maintaining them properly, and upgrading to advanced models can significantly improve crane performance and reduce operational costs. For industrial facilities relying on overhead cranes, understanding and investing in high-quality end trucks is a strategic choice that drives productivity and safety.

Leave a Reply