Introduction

In busy warehouses and industrial facilities, forklifts and pedestrians often share the same space—creating serious safety risks. If you’ve noticed a bright blue light projected on the floor ahead of a moving forklift, you might be wondering what it’s for and whether it really helps. Fork Truck Blue Safety Light systems are designed to reduce accidents by providing an early visual warning that a forklift is approaching.

In this comprehensive guide, you’ll learn what a fork truck blue safety light is, how it works, why it’s effective, and how to choose and use one properly. Whether you’re a safety manager, warehouse supervisor, or forklift operator, this article focuses on solving real safety problems—not just explaining the technology.

What Is a Fork Truck Blue Safety Light?

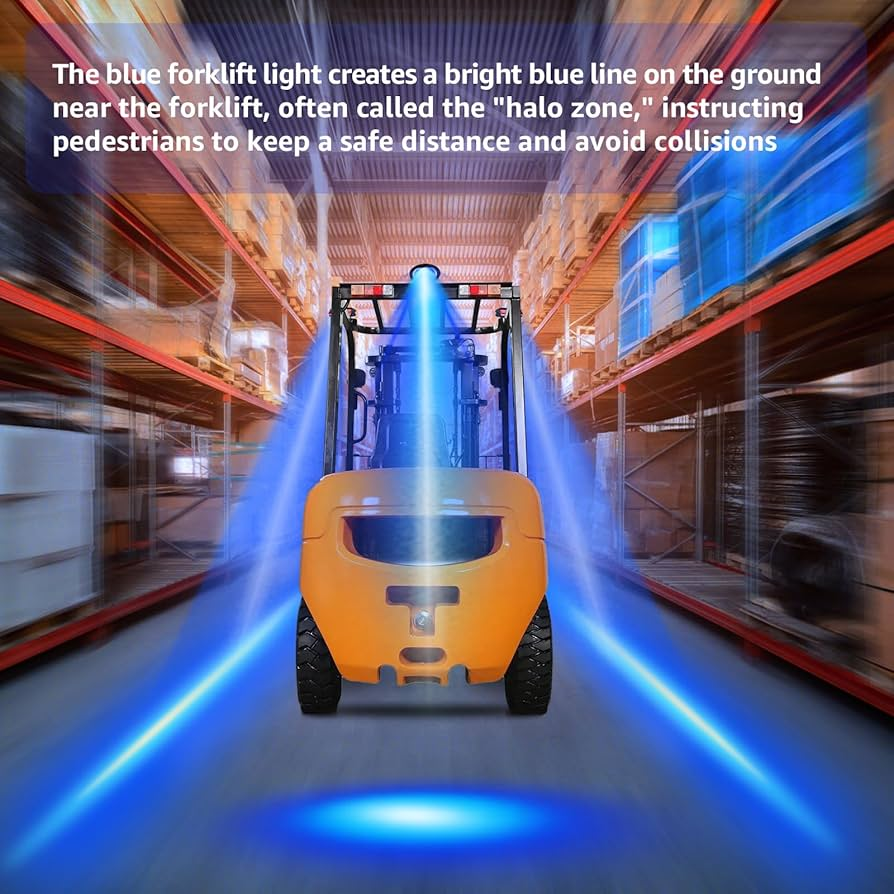

A Fork Truck Blue Safety Light is a high-intensity LED light mounted on a forklift (also called a fork truck) that projects a bright blue spot or line onto the floor in front of—or sometimes behind—the vehicle.

Its main purpose:

- Warn pedestrians of an approaching forklift

- Improve visibility in blind corners and intersections

- Reduce collisions in noisy environments

Unlike audible alarms, the blue safety light provides a silent, visual warning that works even in loud warehouses.

Read too: Top Trucking Companies That Still Have Manual Transmissions

For general background on forklifts as industrial vehicles, you can reference:

https://en.wikipedia.org/wiki/Forklift

How Does a Fork Truck Blue Safety Light Work?

The system is simple but highly effective.

How it operates:

- The blue LED light is powered by the forklift’s electrical system

- When the forklift is moving, the light projects a bright blue spot or line on the floor

- The light appears several feet ahead of the forklift

- Pedestrians see the light before the forklift itself becomes visible

Because the blue color contrasts strongly with warehouse floors, it’s easy to notice—even in low-light conditions.

Why Is Blue Used Instead of Other Colors?

This is one of the most common questions.

Reasons blue is preferred:

- High contrast on concrete floors

- Less common in warehouse environments

- Easy for the human eye to detect in peripheral vision

- Not easily confused with emergency exit signs or red warning lights

Studies in industrial safety show that blue light stands out better than white or amber in busy visual environments.

Why Fork Truck Blue Safety Lights Are Important for Safety

Forklift-related accidents are a major concern in industrial settings.

Common forklift hazards:

- Blind corners and intersections

- Poor visibility due to shelving

- High ambient noise masking alarms

- Pedestrian complacency

A fork truck blue safety light addresses these issues by providing advance visual warning, reducing reaction time for pedestrians.

Safety insight: Visual warnings are processed faster by the brain than sound in noisy environments, making blue safety lights especially effective.

Fork Truck Blue Safety Light vs Audible Alarms

Audible alarms like beepers have been used for decades—but they’re not always effective.

Comparison Table: Blue Safety Light vs Audible Alarm

| Feature | Blue Safety Light | Audible Alarm |

|---|---|---|

| Works in noisy areas | ✅ Yes | ❌ Often ignored |

| Directional warning | ✅ Yes | ❌ No |

| Silent operation | ✅ Yes | ❌ No |

| Pedestrian response time | Fast | Slower |

| Noise pollution | None | High |

This comparison explains why many facilities now use both systems together for maximum safety.

Where Are Fork Truck Blue Safety Lights Most Effective?

Blue safety lights are particularly useful in environments with:

- High pedestrian traffic

- Tight aisles

- Blind corners

- Poor lighting

- Loud machinery

Common use locations:

- Warehouses

- Distribution centers

- Manufacturing plants

- Cold storage facilities

- Retail backrooms

In these settings, early visual warnings significantly reduce near-miss incidents.

Do Fork Truck Blue Safety Lights Reduce Accidents?

Yes—when properly installed and used correctly.

Documented benefits include:

- Fewer pedestrian-forklift collisions

- Reduced near-miss incidents

- Improved situational awareness

- Increased safety culture awareness

Many safety managers report noticeable reductions in incidents within weeks of installation.

Types of Fork Truck Blue Safety Lights

Not all blue safety lights are the same.

Common types:

- Spot lights: Project a round blue dot

- Line lights: Project a straight blue line

- Dual-direction lights: Front and rear projection

Each type serves a slightly different purpose depending on facility layout.

Spot Light vs Line Light: Which Is Better?

Comparison Table

| Feature | Blue Spot Light | Blue Line Light |

|---|---|---|

| Warning distance | Moderate | Longer |

| Best for | General use | Aisles & corners |

| Visual clarity | High | Very high |

| Installation complexity | Low | Low |

Many facilities choose line lights for aisle-heavy layouts and spot lights for general traffic areas.

How Far Ahead Should the Blue Light Project?

Projection distance matters for effectiveness.

Recommended range:

- 6–15 feet (1.8–4.5 meters) ahead of the forklift

- Longer distances for higher travel speeds

- Shorter distances in tight spaces

The goal is to give pedestrians enough time to react without causing confusion.

Step-by-Step: How Fork Truck Blue Safety Lights Are Installed

Installation should always follow manufacturer guidelines, but the general process is similar.

Basic installation steps:

- Turn off and disconnect forklift power

- Mount the light on the overhead guard or rear frame

- Connect wiring to forklift power supply

- Secure cables away from moving parts

- Adjust projection angle and distance

- Test light operation in motion

Professional installation is recommended for large fleets.

Common Mistakes When Using Blue Safety Lights

Even effective safety tools can fail if misused.

Avoid these mistakes:

- Setting projection too close to the forklift

- Installing only on some forklifts

- Failing to train pedestrians

- Relying on blue lights alone

- Poor maintenance or dirty lenses

Blue safety lights should complement, not replace, other safety measures.

Are Fork Truck Blue Safety Lights Required by Law?

In the U.S., blue safety lights are not specifically mandated, but they support compliance with general workplace safety standards that require employers to reduce known hazards.

Many companies adopt them as part of:

- Proactive safety programs

- Accident prevention initiatives

- Insurance risk reduction strategies

They are widely considered a best practice rather than a legal requirement.

Cost vs Value: Are Blue Safety Lights Worth It?

Typical cost:

- $50–$200 per light (depending on quality and type)

Value gained:

- Reduced injury risk

- Fewer downtime incidents

- Lower workers’ compensation claims

- Improved employee confidence

When compared to the cost of a single accident, blue safety lights offer exceptional ROI.

Training: Why Blue Lights Still Require Human Awareness

Technology alone doesn’t guarantee safety.

Best training practices:

- Teach pedestrians what the blue light means

- Reinforce “see blue, stop and look” behavior

- Include blue lights in safety briefings

- Post visual signage explaining the system

A trained workforce multiplies the effectiveness of the light.

Maintenance and Inspection Tips

To keep the system reliable:

Routine checks:

- Clean lenses weekly

- Inspect wiring monthly

- Verify brightness and alignment

- Replace damaged housings immediately

Consistent maintenance ensures the light remains visible and effective.

Fork Truck Blue Safety Light: Pros and Cons

Advantages vs Limitations

| Advantages | Limitations |

|---|---|

| High visibility | Requires training |

| Silent warning | Not a complete solution |

| Works in noisy areas | Needs proper setup |

| Improves reaction time | Can be ignored if overused |

Understanding both sides helps facilities use the system wisely.

FAQ: Fork Truck Blue Safety Light

What Is a Fork Truck Blue Safety Light Used For?

It provides a visual warning to pedestrians that a forklift is approaching, especially in blind or noisy areas.

Are Blue Safety Lights Better Than Beeping Alarms?

They are often more effective in noisy environments, but work best when used together with audible alarms.

How Far Ahead Should the Blue Light Be Visible?

Typically 6–15 feet, depending on forklift speed and facility layout.

Do Blue Safety Lights Work in Bright Warehouses?

Yes. High-intensity LEDs are designed to remain visible even in well-lit environments.

Can Blue Safety Lights Prevent All Forklift Accidents?

No. They reduce risk but must be combined with training, clear traffic rules, and operator awareness.

Conclusion

A Fork Truck Blue Safety Light is a simple yet powerful tool that dramatically improves awareness in busy industrial environments. By providing a clear, silent, and early visual warning, it helps pedestrians react sooner and reduces the risk of serious forklift-related accidents.

While it’s not a standalone solution, when combined with proper training, traffic management, and operator discipline, the blue safety light becomes an essential part of a modern warehouse safety strategy.

If this guide helped you understand forklift safety better, share it on social media to help create safer workplaces everywhere.

Leave a Reply