Introduction

If your water truck isn’t spraying properly or you notice uneven water flow, the culprit might be a worn-out water truck air valve diaphragm. This small yet critical part ensures that air pressure and water flow are controlled efficiently. Without it, your truck can’t deliver water safely or reliably.

In this guide, we’ll explain what it does, how much it costs, common failure signs, and step-by-step replacement tips.

Read too: Franklin Truck Parts Near Me: Your Complete Guide to Local Truck Parts & Repair Solutions

What Is a Water Truck Air Valve Diaphragm?

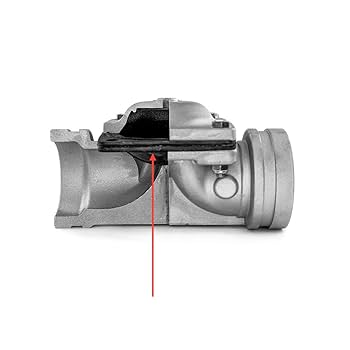

A water truck air valve diaphragm is a flexible rubber or synthetic membrane inside the air-actuated valve system. It moves in response to air pressure, controlling water release from the truck’s tank to the spray bars or hoses.

Key roles:

- Controls flow: Ensures steady water distribution.

- Prevents leaks: Creates an airtight and watertight seal.

- Supports safety: Keeps high-pressure systems operating correctly.

Water trucks for construction, mining, and agriculture rely heavily on this part for daily operations.

How Much Does a Water Truck Air Valve Diaphragm Cost?

Prices vary based on material and manufacturer.

| Type | Average Cost Range | Notes |

|---|---|---|

| Standard rubber diaphragm | $40 – $75 | Common, cost-effective |

| Reinforced synthetic diaphragm | $60 – $120 | More durable, resists chemicals |

| OEM brand diaphragm | $80 – $150 | Exact fit, higher reliability |

👉 Labor for replacement: $150 – $300, depending on accessibility.

Signs Your Air Valve Diaphragm Needs Replacement

- Uneven or weak water spray.

- Air leaks from the valve assembly.

- Water truck not responding when controls are activated.

- Visible cracks or wear on diaphragm (if inspected).

- Frequent pressure loss during operation.

How to Replace a Water Truck Air Valve Diaphragm

Replacing a diaphragm is straightforward if you follow safety procedures.

- Shut down system: Turn off engine and release all air pressure.

- Access valve housing: Remove protective cover or mounting screws.

- Remove old diaphragm: Inspect for cracks, warping, or brittleness.

- Install new diaphragm: Align correctly with valve housing.

- Reassemble housing: Tighten bolts to manufacturer torque specs.

- Test system: Re-pressurize and check for leaks and smooth operation.

Pro Tip: Always keep at least one spare diaphragm on hand for job sites to avoid costly downtime.

Diaphragm Material Comparison

| Material | Pros | Cons |

|---|---|---|

| Rubber | Affordable, flexible | Wears faster in extreme heat |

| Nitrile | Oil and fuel resistant | Higher cost |

| EPDM | Excellent chemical resistance | Not ideal for fuel contact |

| Silicone | High-temp tolerance | Less durable in abrasive conditions |

Benefits of Timely Diaphragm Replacement

- Reduces downtime: Prevents breakdowns on-site.

- Saves money: Avoids costly valve replacements.

- Improves efficiency: Ensures consistent water spray.

- Boosts safety: Keeps air and water systems balanced.

Expert Insight

According to the American Society of Mechanical Engineers (ASME), small sealing components like diaphragms are “often the most critical weak point in valve systems,” highlighting the importance of proactive inspection and timely replacement.

FAQ: Water Truck Air Valve Diaphragm

1. How often should I replace a water truck air valve diaphragm?

Typically every 12–24 months, depending on usage intensity and operating conditions.

2. Can I replace the diaphragm myself?

Yes, if you have basic mechanical skills. However, professional replacement ensures proper sealing and avoids safety risks.

3. What happens if I ignore a failing diaphragm?

You risk poor spray performance, air leaks, and even valve system failure, which can cause costly downtime.

4. Are aftermarket diaphragms reliable?

Yes—if sourced from reputable brands. OEM options guarantee fit but cost more.

5. Where can I learn more about valve diaphragms?

Check out the basics of valve mechanics on Wikipedia.

Conclusion

The water truck air valve diaphragm may be a small part, but it plays a huge role in keeping your truck reliable and efficient. By knowing the costs, signs of failure, and replacement steps, you can avoid downtime and keep your operations smooth.

👉 If this article was helpful, share it with other fleet managers or operators—it could save them time, money, and stress in the long run!

Leave a Reply