If your rig drifts, chews through steer tires, or feels vague at highway speed, you may need a Big Truck Front End Alignment. Alignment on heavy trucks is more than comfort—it directly affects tire life, fuel economy, and safety. This guide explains what to check, typical specs, and the exact steps technicians use so you can speak the same language at the shop.

Big Truck Front End Alignment — What Is It, Exactly?

A Big Truck Front End Alignment sets three primary angles so the tires meet the road correctly:

- Caster (steering stability)

- Camber (tire contact patch)

- Toe (tire direction)

Read too: Top Trucking Companies That Still Have Manual Transmissions

On heavy-duty trucks, small deviations create big costs because loads, long wheelbases, and high mileage magnify wear. For background on alignment geometry, see the overview on Wikipedia:

https://en.wikipedia.org/wiki/Wheel_alignment

The Three Angles That Matter (With Visual Cues)

4

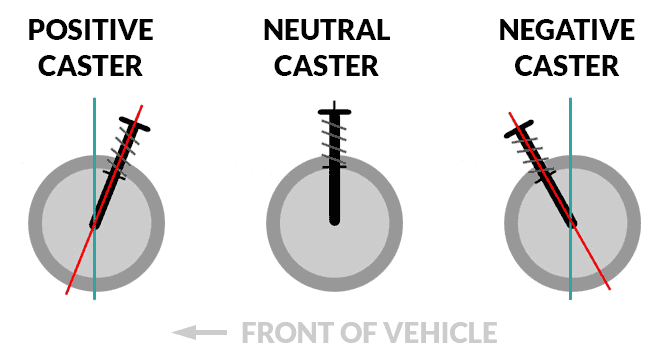

Caster (°)

- Tilt of the steering pivot front-to-back

- More positive caster = better straight-line stability

Camber (°)

- Tilt of the tire inward/outward at the top

- Incorrect camber = edge tire wear

Toe (inches or mm)

- Distance difference between front and rear of tires

- Incorrect toe = feathered tread and wandering

Symptoms You Shouldn’t Ignore

| Symptom | Likely Angle | What You’ll Notice |

|---|---|---|

| Truck pulls left/right | Camber/Caster | Constant steering correction |

| Feathered tread | Toe | Rough feel when sliding hand on tread |

| Outer edge wear | Camber | Shoulder bald, center OK |

| Steering wheel off-center | Toe | Crooked wheel on straight road |

| Tire cupping | Multiple | Wavy dips around tread |

Fleets report that poor alignment can reduce steer tire life by 30–50%.

Typical Heavy Truck Alignment Specs (General Ranges)

Specs vary by axle and manufacturer, but these ranges are common for Class 7–8 trucks.

| Angle | Typical Range |

|---|---|

| Caster | +3.0° to +5.0° |

| Camber | 0° to +0.5° |

| Toe | 1/16″ to 1/8″ toe-in |

Always defer to axle maker specs (Dana, Meritor, Hendrickson, etc.).

Why Big Trucks Go Out of Alignment Frequently

- Potholes and curb strikes

- Worn kingpins or tie-rod ends

- Uneven loads

- Suspension bushing wear

- Frame flex over time

Even a minor impact can shift toe enough to start rapid tire wear within 1,000 miles.

Step-by-Step: How Shops Perform a Big Truck Front End Alignment

Step 1 — Pre-Inspection (10–15 minutes)

Technician checks:

- Kingpins

- Tie rods

- Wheel bearings

- Air pressure set to spec

Alignment is useless if parts are worn.

Step 2 — Mount Sensors & Calibrate

Digital heads clamp to wheels. Truck sits level on alignment rack.

Step 3 — Measure Caster & Camber

Adjusted using:

- Shims

- Eccentric bushings

- Axle adjustments (depending on suspension)

Step 4 — Set Toe Precisely

Measured in fractions of an inch using lasers/computers. Toe is the most tire-sensitive setting.

Step 5 — Center Steering Wheel

Critical for driver comfort and tracking.

Step 6 — Road Test

Confirms no pull and proper return-to-center.

DIY Checks Drivers Can Do (Before the Shop)

- Check tire pressure with a calibrated gauge

- Inspect tread with your palm for feathering

- Measure toe roughly with a tape measure front vs rear of tires

- Look for uneven ride height (air suspension issue)

These checks help you explain symptoms clearly.

Cost of Big Truck Front End Alignment

| Service | Typical Cost (US) |

|---|---|

| Basic front alignment | $180–$350 |

| With suspension repairs | $400–$900 |

| Full tractor + trailer alignment | $600–$1,200 |

Compared to $600–$900 per steer tire, alignment pays for itself quickly.

Pros vs Cons of Regular Alignment

Pros

- Extends tire life dramatically

- Better fuel economy (1–3% improvement reported by fleets)

- Less driver fatigue

- Safer highway tracking

Cons

- Downtime during service

- Requires specialized heavy-duty shop

How Often Should You Align a Big Truck?

Recommended:

- Every 80,000–100,000 miles

- After hitting major potholes/curbs

- When replacing steer tires

- After suspension or steering repairs

Real-World Case Example

A regional fleet noticed steer tires lasting only 55,000 miles. After correcting toe from 3/16″ out to 1/16″ in, average life increased to 92,000 miles. That’s thousands saved per truck annually.

Common Mistakes That Ruin Alignment

- Aligning with worn kingpins

- Ignoring ride height settings

- Not centering steering wheel

- Mixing tire sizes on steer axle

- Skipping torque checks after adjustment

FAQ — Big Truck Front End Alignment

Q1: What angle causes the most tire wear?

Toe. Even slight errors destroy tread quickly.

Q2: Can bad alignment affect fuel economy?

Yes. Misalignment increases rolling resistance.

Q3: Should I align after replacing kingpins?

Absolutely. Geometry changes after replacement.

Q4: Why does my truck pull only when loaded?

Load shifts suspension height, altering angles.

Q5: Do new tires require alignment?

Yes. Install alignment when mounting new steers.

Q6: Can I align without a rack?

Only rough checks. Precision requires professional equipment.

Conclusion

A proper Big Truck Front End Alignment protects your tires, improves handling, and saves fuel. With heavy trucks, tiny angle errors create big costs fast. Regular checks, clear symptoms, and professional alignment keep your rig tracking straight for the long haul.

If this guide helped you understand alignment better, share it on social media with other drivers and fleet owners who want to cut tire costs and improve safety.

Leave a Reply