Introduction

For service professionals, having a reliable air supply on the road is critical. A gas powered air compressor for service truck ensures you can operate tools, inflate tires, and perform maintenance without relying on electrical hookups. Many technicians face downtime due to underpowered or inefficient compressors, making the right choice essential for productivity and safety.

Why Choose a Gas Powered Air Compressor?

Gas-powered compressors provide mobility, independence, and power that electric units often cannot match:

- Portability: No need for electrical outlets

- High PSI output: Handles heavy-duty tools like impact wrenches and pneumatic hammers

- Continuous operation: Ideal for extended jobs in remote areas

According to industry reports, service vehicles equipped with gas compressors can increase task completion rates by up to 40% compared to standard electric compressors.

Read too: Franklin Truck Parts Near Me: Your Complete Guide to Local Truck Parts & Repair Solutions

Types of Gas Powered Air Compressors for Trucks

- Portable Tank Compressors

- Compact and easy to mount on trucks

- Suitable for smaller tools and inflation tasks

- Belt-Driven Compressors

- Mounted directly on engine or PTO

- High airflow for sustained heavy-duty usage

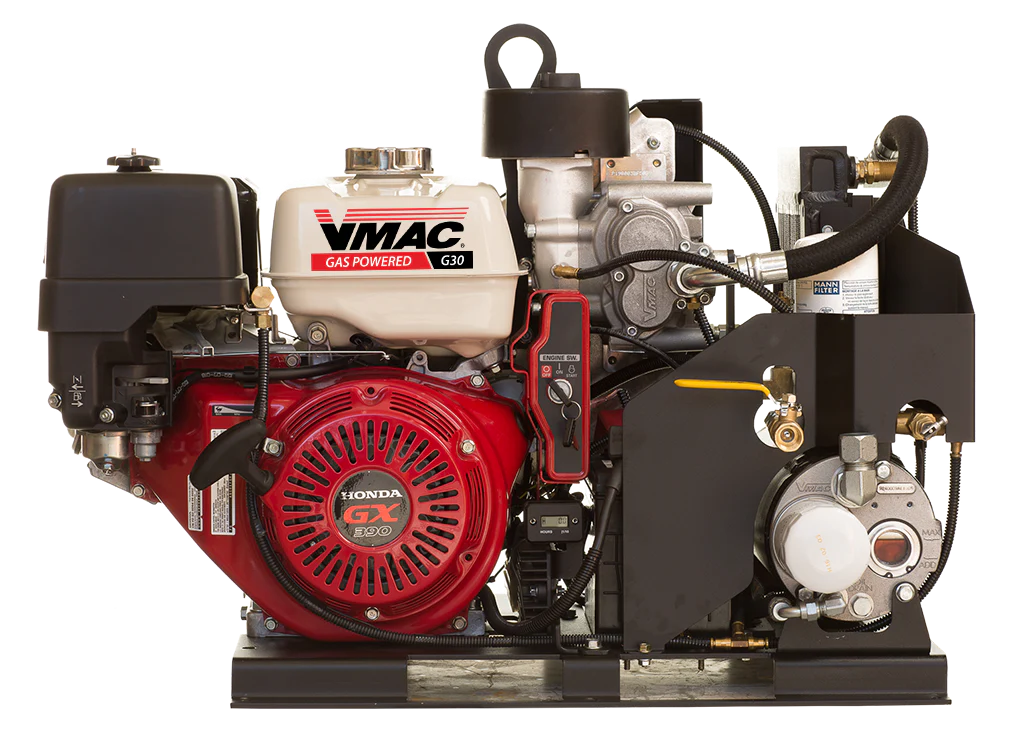

- Rotary Screw Compressors

- Continuous operation with minimal maintenance

- Ideal for mobile workshops and service fleets

Key Features to Look For

When selecting a gas-powered compressor for a service truck, consider:

- CFM (Cubic Feet per Minute): Ensure the output matches the tools you intend to run

- PSI Rating: Higher PSI is better for heavy-duty applications

- Tank Size: Larger tanks allow longer continuous operation without overworking the motor

- Durability: Look for corrosion-resistant tanks and frames

- Fuel Efficiency: Minimize downtime and fuel costs

Installation Tips for Service Trucks

- Choose the Mounting Location:

- Secure near the truck bed or underbody with stable brackets

- Ensure easy access for maintenance and refueling

- Connect Air Lines Safely:

- Use high-quality hoses rated for compressor PSI

- Avoid kinks or sharp bends that reduce airflow

- Secure Fuel Supply:

- Ensure proper ventilation for gasoline-powered engines

- Follow manufacturer instructions for fuel storage and refilling

- Test for Leaks:

- Apply soapy water to fittings and hoses to check for air leaks before use

Advantages vs Disadvantages

| Advantage | Disadvantage |

|---|---|

| Portable and mobile | Requires gasoline refills |

| High PSI output | Louder than electric models |

| Independent of electrical sources | Regular maintenance needed |

| Can power heavy-duty tools | Heavier and bulkier than small electric units |

Maintenance Tips

- Check and change oil regularly (every 100–200 hours depending on manufacturer)

- Inspect hoses and fittings for wear or leaks monthly

- Clean air filters to prevent dust and debris from damaging the engine

- Store in a dry area to prevent corrosion

Pro Tip: Label maintenance dates on the truck dashboard to ensure routine checks are never missed.

FAQ

Q1: Can I run multiple tools at the same time with a gas compressor?

A: Yes, if the CFM rating of the compressor meets the combined requirements of the tools.

Q2: How often should I service a gas-powered air compressor?

A: Perform routine checks monthly, and full service every 6–12 months depending on usage.

Q3: Are gas compressors safe for indoor use?

A: No, gasoline-powered compressors produce fumes; always use outdoors or in well-ventilated areas.

Q4: What is the average lifespan of a truck-mounted gas compressor?

A: With proper maintenance, 8–12 years is typical for professional-grade units.

Q5: Can I use a small portable compressor for heavy-duty truck service?

A: Small compressors may run basic tools but cannot sustain heavy-duty operations for extended periods.

Q6: Is a belt-driven compressor better than a tank-mounted model?

A: Belt-driven compressors provide higher airflow for continuous jobs, while tank-mounted units are more portable and easier to install.

Conclusion

A gas powered air compressor for service truck is an indispensable tool for mobile mechanics, contractors, and service technicians. It ensures reliable air supply, independence from electrical outlets, and high performance for heavy-duty tools. By choosing the right type, installing properly, and maintaining it regularly, you can maximize efficiency and minimize downtime.

Share this guide on Facebook, Twitter, or LinkedIn to help fellow service professionals improve their mobile workshop setup!

Leave a Reply