When it comes to aerial lift maintenance and safety, few names carry the reliability and reputation of Hi Ranger. Whether you’re managing a utility fleet or working in tree care, telecommunications, or electrical services, understanding and sourcing Hi Ranger Bucket Truck Parts is essential for keeping your equipment functional and compliant with safety standards.

In this complete guide, we’ll explore the types of parts available, how to identify what you need, where to buy them, and how to maintain your Hi Ranger aerial lift system effectively.

Why Hi Ranger Bucket Trucks Are an Industry Standard

Hi Ranger, a division of Terex Utilities, has a long-standing reputation for engineering high-performance aerial devices. Known for their bucket trucks, also called cherry pickers or boom trucks, Hi Ranger units are widely used across industries that require workers to safely reach elevated areas.

Their trucks are built to last, but like any piece of heavy equipment, routine maintenance and part replacements are crucial. That’s where knowledge of Hi Ranger Bucket Truck Parts becomes vital.

Types of Hi Ranger Bucket Truck Parts

Hi Ranger bucket truck systems are complex machines composed of mechanical, hydraulic, and electrical systems. Understanding the various categories of parts can help you identify what you need when something wears out or fails.

1. Hydraulic Parts

Hi Ranger aerial lifts rely heavily on hydraulics to function. Common hydraulic parts include:

- Hydraulic pumps and motors

- Hoses and fittings

- Control valves

- Cylinders and seals

- Flow restrictors

Hydraulic systems must be leak-free and well-maintained to avoid operational failure or workplace hazards.

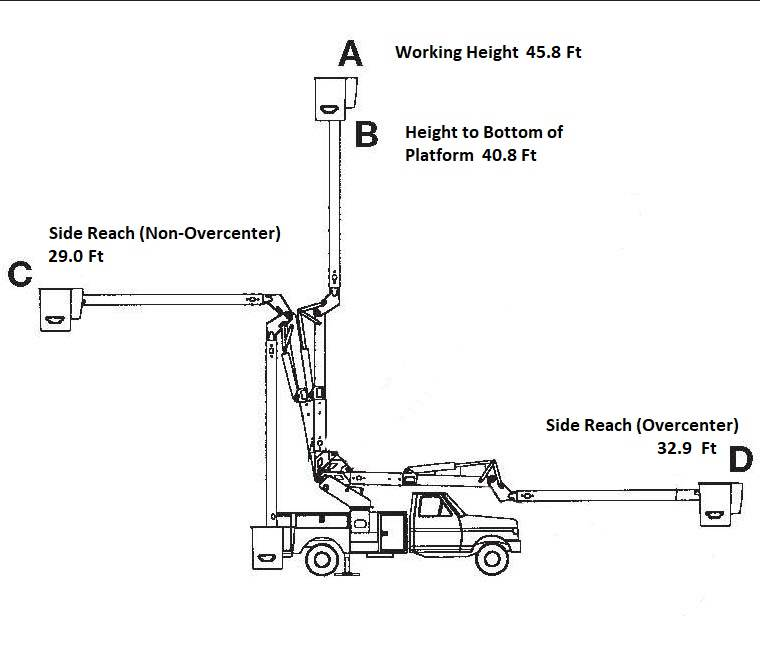

2. Boom Components

The telescopic or articulated boom is the primary lifting mechanism. Parts in this category include:

- Boom arms

- Boom chains

- Wear pads

- Pivot pins and bushings

- Turntable assemblies

Even slight wear in these parts can impact stability and operator safety.

3. Bucket and Platform Parts

The bucket (platform) is where the operator stands. Key components include:

- Fiberglass bucket replacements

- Bucket liners and tool trays

- Step brackets and safety rails

- Leveling systems and linkages

- Fall arrest and safety harness mounts

Keeping the platform secure and level is critical to prevent tipping or falls.

4. Electrical Components

Hi Ranger trucks often use electronic or electro-hydraulic controls:

- Joysticks and toggle switches

- Proximity sensors

- Interlock systems

- Load limit sensors

- Wiring harnesses

If the controls become unresponsive, electrical components are usually the first place to check.

5. Outriggers and Stabilizers

To prevent the truck from tipping, outriggers stabilize the entire unit:

- Outrigger pads

- Hydraulic legs and cylinders

- Level sensors

- Manual lockout valves

A malfunction in this system can cause major safety hazards.

6. Rotational Systems

Hi Ranger’s turret and boom system rotates to give the operator mobility:

- Turntables

- Bearings and seals

- Rotary actuators

- Rotation gearboxes

If rotation is sticky or inconsistent, these parts may need servicing or replacement.

Where to Buy Hi Ranger Bucket Truck Parts

Finding authentic Hi Ranger replacement parts is crucial for safety and performance. Below are some trusted sources:

Authorized Terex Distributors

As the OEM (Original Equipment Manufacturer), Terex and its authorized dealers are the most reliable sources for certified parts.

Aftermarket Part Suppliers

Some reputable aftermarket brands manufacture high-quality compatible parts. Make sure to check:

- Compatibility with your Hi Ranger model

- Warranty options

- Compliance with ANSI or OSHA standards

Online Marketplaces

Websites like eBay and Amazon occasionally offer parts, but be cautious about:

- Seller reputation

- Used or refurbished condition

- Lack of warranty

Local Equipment Dealers

Some independent repair shops and heavy equipment dealers stock Hi Ranger parts or can order them for you. These suppliers often offer repair services, too.

How to Identify the Right Hi Ranger Bucket Truck Parts

Knowing the correct part to order starts with properly identifying your equipment:

Step 1: Locate the Serial Number Plate

Find the serial number plate on your Hi Ranger lift. This tag usually includes:

- Model number

- Serial number

- Manufacturing date

- Voltage or hydraulic specs

Step 2: Consult the Operator’s Manual

Every Hi Ranger aerial lift comes with a manual listing part numbers, diagrams, and maintenance schedules.

If you lost the manual, many versions are available online from Terex or third-party sites.

Step 3: Visual Inspection

If you can’t identify a part from documentation, a photo and measurement can help parts suppliers assist you in sourcing the correct replacement.

Maintaining and Replacing Hi Ranger Bucket Truck Parts

Preventative maintenance saves time, money, and lives. A strong understanding of Hi Ranger Bucket Truck Parts helps operators and fleet managers stay ahead of costly repairs and downtime.

Routine Inspection Checklist

Here’s what you should check regularly:

- Hydraulic hoses for leaks

- Platform for cracks or wear

- Controls for responsiveness

- Boom for wear or corrosion

- Outriggers for stability

When to Replace Parts

- Hydraulic leaks: Replace hoses, seals, or cylinders

- Loose platform: Inspect leveling linkages

- Unusual movement: May indicate turntable or pivot issues

- No power to controls: Likely a switch, wiring, or joystick issue

Recordkeeping

Always document:

- Date of inspection

- Issues found

- Parts replaced

- Downtime

This improves operational planning and regulatory compliance.

Safety Standards and Compliance

Using the right Hi Ranger Bucket Truck Parts is not just about performance—it’s about meeting safety standards from organizations like:

- OSHA (Occupational Safety and Health Administration)

- ANSI (American National Standards Institute)

- DOT (Department of Transportation) for road-legal compliance

Annual Inspections

Per ANSI A92 and OSHA regulations, aerial lifts must be inspected annually by a qualified technician.

Using OEM or certified replacement parts helps meet these inspection criteria.

Common Hi Ranger Models and Their Parts

Hi Ranger produces various models, and each requires specific parts. Here are some common models:

1. Hi Ranger TL Series

- Popular for telecommunications

- Needs parts like 2-section booms, compact outriggers

2. Hi Ranger XT Series

- Articulating/telescopic booms

- Uses leveling mechanisms, dual control systems

3. Hi Ranger LT40 & L60

- Found in utility fleets

- Often require heavy-duty outrigger and turntable parts

Always verify your exact model before ordering.

Tips for Prolonging the Life of Your Hi Ranger Equipment

- Train operators on correct usage

- Store indoors when not in use

- Use rust inhibitors on exposed metal parts

- Follow the OEM maintenance schedule

- Only use certified parts to avoid equipment failure

Conclusion: Why Knowing Hi Ranger Bucket Truck Parts Matters

Maintaining and understanding Hi Ranger Bucket Truck Parts is vital for any operator or fleet manager who values uptime, safety, and equipment longevity. From hydraulic systems and booms to electrical components and outriggers, every part plays a crucial role in safe and efficient operation.

By sourcing the correct parts, performing regular maintenance, and keeping accurate records, you not only protect your investment — you also ensure the safety of the people who rely on it every day.

Leave a Reply