Choosing the wrong Loading Ramps For Box Trucks can lead to damaged cargo, bent ramps, or serious injuries. Ramp length, angle, material, and weight rating must match your truck height and load type.

This guide explains how to calculate the correct ramp size, compare materials, and load safely every time.

What Are Loading Ramps For Box Trucks?

4

Loading ramps bridge the height gap between the ground and the cargo floor of a box truck so equipment, pallets, or machines can roll in safely. Most are made from aluminum or steel and used in pairs.

For general background on ramp design and mechanics, see Loading ramp:

https://en.wikipedia.org/wiki/Loading_ramp

Why Ramp Length Matters More Than You Think

Short ramps create steep angles. Steep angles cause:

- Equipment scraping

- Loss of traction

- Tip-over risk

- Excess strain on ramp hinges

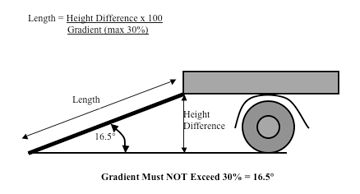

Ideal Ramp Angle

15° or less for wheeled equipment

12° or less for low-clearance machines

How to Calculate the Correct Ramp Length

Step-by-Step Formula

- Measure cargo floor height (example: 36 inches)

- Choose safe angle (15°)

- Use formula:

Ramp Length=sin(Angle)Height

For 36” height at 15°:

Ramp ≈ 11.5 feet (138 inches)

This is why many professionals use 10–12 ft ramps for box trucks.

Aluminum vs Steel Ramps

| Feature | Aluminum | Steel |

|---|---|---|

| Weight | Lightweight | Heavy |

| Rust resistance | Excellent | Needs coating |

| Portability | Easy | Harder |

| Strength | High | Very high |

| Best for | Daily use | Extreme loads |

Aluminum is preferred for frequent loading because it’s easier to handle.

Read too: Franklin Truck Parts Near Me: Your Complete Guide to Local Truck Parts & Repair Solutions

Weight Capacity — How Much Do You Really Need?

Never match ramp rating to equipment weight exactly.

Safety Rule

Ramp capacity should be 2× the equipment weight

| Equipment | Weight | Recommended Ramp Rating (pair) |

|---|---|---|

| Lawn mower | 900 lbs | 2,000 lbs |

| Pallet jack load | 2,000 lbs | 4,000 lbs |

| ATV | 1,200 lbs | 3,000 lbs |

| Mini skid steer | 3,000 lbs | 8,000 lbs |

Arched vs Straight Ramps

4

Arched ramps reduce the breakover angle, preventing low equipment from scraping at the top.

Choose arched ramps if you load:

- Motorcycles

- Floor machines

- Low-clearance equipment

Step-by-Step: Safe Loading Procedure

- Park on level ground

- Engage parking brake

- Place ramps evenly spaced

- Ensure ramp lips sit fully on truck edge

- Use straps or pins if provided

- Walk equipment slowly up the ramp

- Keep body weight low and centered

Never rush the climb.

Common Mistakes That Cause Ramp Failure

| Mistake | Result |

|---|---|

| Using ramps too short | Equipment scraping |

| No ramp securing | Ramp slips |

| Overloading | Ramp bending |

| Wet muddy ramps | Slip hazard |

| Uneven ground | Ramp twist |

Folding Ramps vs Separate Ramps

| Feature | Folding Ramp | Separate Ramps |

|---|---|---|

| Storage | Attached | Portable |

| Setup time | Faster | Flexible spacing |

| Weight | Heavier | Lighter per piece |

| Best for | Delivery trucks | Equipment hauling |

Best Ramp Surface for Traction

Look for:

- Serrated rungs

- Punch-plate surface

- Raised traction ribs

Avoid smooth surfaces that become slippery when wet.

Real-World Scenario

A contractor loads a 2,500-lb floor scrubber into a 40” high box truck using 7 ft ramps. The angle is too steep, causing the machine to scrape and lose traction.

Switching to 12 ft arched ramps solves the issue immediately.

Maintenance Tips for Long Ramp Life

- Inspect welds monthly

- Clean mud and oil after use

- Store dry to prevent corrosion

- Check lip edge for bending

FAQ — Loading Ramps For Box Trucks

Q1: What ramp length is best for a 36” floor height?

10–12 feet for safe angle.

Q2: Can I use one wide ramp instead of two?

Only for pallet jacks, not wheeled equipment.

Q3: Are aluminum ramps strong enough?

Yes, if properly rated.

Q4: Why are my ramps bending?

They are under-rated for the load.

Q5: Should ramps be secured to the truck?

Yes, always if possible.

Conclusion

The right Loading Ramps For Box Trucks make loading safer, faster, and easier while protecting your equipment and your crew. By choosing proper length, capacity, and surface design, you eliminate the most common loading risks.

If this guide helped you select better ramps, share it on social media to help others load smarter and safer.

Leave a Reply