Managing truck loads efficiently is a vital part of any fleet operation. For trucks equipped with spring suspension systems, ensuring that cargo is loaded within legal and safe limits can be a challenge without the right tools. This is where On-Board Truck Scales For Spring Suspension come in. These specialized systems allow drivers and fleet operators to measure axle weights in real time, avoiding overweight fines, improving safety, and streamlining operations.

In this comprehensive guide, we’ll cover everything you need to know about on-board truck scales, how they work with spring suspension, their advantages, installation tips, and how to choose the right system for your fleet.

Read too: Port Authority Snapback Trucker Cap: The Stylish and Practical Headwear You Need Today

What Are On-Board Truck Scales For Spring Suspension?

On-board truck scales for spring suspension are weight monitoring systems that are specifically designed to work with trucks or trailers equipped with leaf spring or coil spring suspensions. Unlike air suspension systems that use pressure sensors, spring suspensions require load sensors or strain gauges that calculate weight based on axle deflection or load pin technology.

These systems are typically mounted directly to the vehicle and provide real-time weight readings for each axle group or gross vehicle weight (GVW). They’re commonly used in industries like construction, logistics, agriculture, waste hauling, and heavy-duty freight.

Why Are These Scales Important for Spring Suspensions?

Spring suspensions are common in heavy-duty vehicles due to their durability and lower cost compared to air suspensions. However, unlike air ride systems, spring suspensions lack air pressure changes that can be monitored to estimate load weight. This makes it more difficult to estimate load weight without a scale, increasing the risk of:

- Overweight violations

- Uneven loading

- Reduced braking efficiency

- Premature wear on tires and axles

Installing on-board truck scales for spring suspension solves this issue by giving drivers accurate weight data without needing to visit a truck stop or external weigh station.

Types of On-Board Truck Scales For Spring Suspension

Several different types of on-board scales are compatible with spring suspension systems. The most common include:

1. Load Cell-Based Systems

These use load cells or load pins installed on the suspension system or axle points. They measure the force exerted on the axle and convert it to weight data. They offer high accuracy and are popular in dump trucks, flatbeds, and refuse trucks.

2. Strain Gauge Sensors

These are attached to structural points on the vehicle frame or axles and measure how much the material flexes under load. The data is processed and converted to display load weights. These are often more cost-effective and are suitable for trucks with limited mounting space.

3. Wireless Scale Systems

These newer systems offer Bluetooth or wireless communication between sensors and a handheld display or mobile app. Ideal for fleets looking for modern, flexible solutions.

Key Features to Look for in On-Board Scales for Spring Suspension

When selecting the right scale for your truck or trailer, consider these features:

- ✅ Accuracy: Look for systems with proven precision within ±1% of GVW

- ✅ Real-Time Monitoring: Scales should offer instant weight feedback as loads are added or removed

- ✅ Axle Group Readings: Know not just gross weight but axle distribution to ensure balanced loading

- ✅ Ease of Installation: Systems should be installable with minimal welding or modification

- ✅ Durability: Must withstand harsh environments—dust, mud, water, and temperature fluctuations

- ✅ Calibration & Maintenance: Should be easy to calibrate and maintain periodically

Benefits of Using On-Board Truck Scales For Spring Suspension

Investing in a quality on-board scale system brings numerous advantages to truckers, fleet managers, and owner-operators alike:

✔️ Avoid Overweight Fines

DOT regulations are strict on weight compliance. Exceeding the legal weight limit can result in steep penalties. A scale helps you stay within the limits.

✔️ Improve Safety

An overloaded or unevenly loaded truck poses a major safety risk on highways, particularly affecting braking, handling, and tire wear.

✔️ Increase Operational Efficiency

By knowing how much you’re hauling, you can maximize payloads without risking overweight tickets. This improves revenue per trip.

✔️ Eliminate Downtime at Weigh Stations

With onboard weight data, drivers can bypass weigh stations where allowed, saving time and fuel.

✔️ Reduce Maintenance Costs

Proper loading reduces unnecessary stress on suspension, tires, and brakes—leading to longer component life and fewer repairs.

Installation Tips for On-Board Truck Scales

Installing on-board truck scales for spring suspension isn’t overly complicated, but proper setup is key for accuracy.

Step-by-Step Overview:

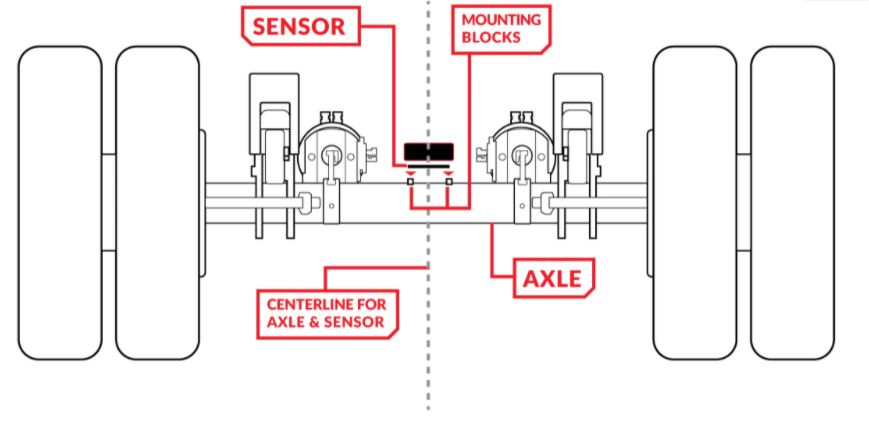

- Select Mounting Points: Typically on the rear spring hangers or axles. Ensure the surface is clean and flat.

- Attach Load Sensors or Strain Gauges: Follow the manufacturer’s instructions precisely to avoid misreading data.

- Route Wiring (if applicable): Keep wires protected from the elements, abrasion, and moving parts.

- Mount Display Module or Connect Mobile App: Choose a location easily viewable by the driver.

- Calibrate the System: Use known weights to calibrate the display, often with the help of a scale facility.

- Regular Maintenance: Periodic recalibration and inspection are recommended every 6–12 months.

Top Brands Offering On-Board Truck Scales for Spring Suspension

Several trusted manufacturers offer reliable solutions for spring suspension systems:

- Right Weigh Inc. – Known for budget-friendly, accurate load gauges for spring and air suspension

- Vulcan On-Board Scales – Industry leader offering systems for dump trucks, refuse trucks, and more

- LoadMan – Specializes in on-board scales for refuse and aggregate trucks

- Haul Weight – Offers digital and wireless scale systems for fleet management

- Air-Weigh – Though focused on air suspensions, they offer hybrid models adaptable to spring setups

Industries That Rely on These Systems

Many industries benefit from on-board truck scales for spring suspension, including:

- 🚧 Construction & Aggregates: Dump trucks, flatbeds, and material haulers

- 🗑️ Waste Management: Garbage trucks often rely on spring suspensions and need weight monitoring

- 🌾 Agriculture: Grain haulers and silage trucks

- 📦 Logistics & Delivery: Box trucks with spring suspensions in local freight

- 🛻 Towing & Recovery: Ensures safe and legal towing weight

Common Questions (FAQ)

❓ Do I need to recalibrate the scale often?

Yes. Most systems require recalibration every 6–12 months depending on usage and conditions.

❓ Are these systems legal for weight compliance bypasses?

Some jurisdictions allow bypass if certified systems are in use, but always verify with local DOT regulations.

❓ Can I transfer the system to another truck?

Yes, many systems are modular and can be transferred with some effort and recalibration.

❓ How accurate are on-board truck scales for spring suspension?

Most reputable brands offer accuracy within 1–2% of actual weight when properly calibrated.

Final Thoughts

On-board truck scales for spring suspension are a game-changer for fleet operators and owner-operators alike. These tools make it easier to stay legal, load smarter, and improve road safety. While the upfront investment varies, the return in terms of fewer fines, less downtime, and better operational control makes it well worth the cost.

Whether you’re hauling gravel, collecting refuse, or delivering freight, equipping your spring suspension truck with the right on-board scale system helps you take control of your payload and peace of mind on the road.

Leave a Reply