When your semi truck AC not blowing cold air, long drives can quickly turn uncomfortable—or even unsafe. Heat fatigue reduces focus and reaction time, especially during summer hauls. This guide explains why your semi truck AC may stop cooling and shows you how to diagnose and fix the problem efficiently.

Why Is My Semi Truck AC Not Blowing Cold Air?

A semi truck AC system relies on multiple components working together. When one part fails, cooling performance drops or disappears entirely.

Common Symptoms:

- Warm or mildly cool air from vents

- AC works intermittently

- Airflow is normal, but not cold

- AC stops cooling while idling

Understanding the root cause is the first step to an effective repair.

Read too: Top Trucking Companies That Still Have Manual Transmissions

How a Semi Truck AC System Works (Quick Overview)

Before troubleshooting, it helps to understand the basics.

Main Components:

- Compressor

- Condenser

- Evaporator

- Expansion valve

- Refrigerant (usually R-134a or R-1234yf)

The system compresses refrigerant, removes heat, and circulates cold air through the cab.

You can learn more about automotive air conditioning fundamentals here:

👉 https://en.wikipedia.org/wiki/Air_conditioning

Most Common Reasons Semi Truck AC Is Not Blowing Cold

1. Low Refrigerant Level

This is the #1 cause of AC problems in semi trucks.

Why it happens:

- Small leaks over time

- Worn seals or hoses

- Poor previous servicing

Signs:

- AC blows warm air

- Compressor cycles frequently

According to fleet maintenance data, over 60% of AC failures are linked to low refrigerant levels.

2. Faulty AC Compressor

The compressor is the heart of the system.

Symptoms of compressor failure:

- Loud clicking or grinding noises

- AC clutch not engaging

- No cold air at all

If the compressor fails completely, refrigerant won’t circulate.

3. Clogged or Damaged Condenser

The condenser releases heat from the refrigerant.

Common issues:

- Road debris blocking airflow

- Bent fins

- Oil contamination

Poor heat dissipation means warm air inside the cab.

4. Electrical or Sensor Problems

Modern semi trucks rely heavily on electronics.

Possible electrical issues:

- Blown fuses

- Faulty pressure switches

- Bad wiring connections

Even a small sensor malfunction can disable cooling.

5. Expansion Valve or Orifice Tube Failure

These parts regulate refrigerant flow.

When they fail:

- AC may blow cold briefly, then warm

- Frost may appear on lines

- Uneven cooling

Step-by-Step: How to Diagnose Semi Truck AC Not Blowing Cold Air

Follow these steps in order to avoid unnecessary repairs.

Step 1: Check Airflow

- Ensure vents blow strong air

- Weak airflow may indicate blower issues, not AC failure

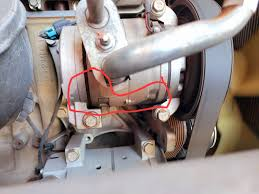

Step 2: Inspect the AC Clutch

- Start engine

- Turn AC to max

- Look for clutch engagement

If it doesn’t engage, electrical or refrigerant issues are likely.

Step 3: Check Refrigerant Pressure

- Use an AC manifold gauge

- Low-pressure side should typically read 25–45 PSI

- High-pressure side: 200–350 PSI (ambient dependent)

⚠️ Always wear protective gloves and eyewear.

Step 4: Inspect for Leaks

- Look for oily residue on hoses

- Use UV dye if available

- Check compressor seals

Step 5: Scan for Fault Codes

- Use a diagnostic scanner

- HVAC-related fault codes often pinpoint the issue

DIY Fixes vs Professional Repairs

What You Can Do Yourself

- Replace cabin air filter

- Clean condenser fins

- Check fuses and relays

When to Call a Professional

- Compressor replacement

- Refrigerant recovery and recharge

- Electrical diagnostics

Cost Breakdown: Semi Truck AC Repairs

| Repair Type | Average Cost (USD) |

|---|---|

| Refrigerant recharge | $150–$350 |

| Compressor replacement | $1,200–$2,500 |

| Condenser replacement | $600–$1,200 |

| Electrical repair | $200–$800 |

Preventive maintenance often costs far less than emergency repairs.

Pros and Cons of Fixing AC Immediately

✅ Advantages

- Driver comfort

- Improved alertness

- Protects electronic components

- Prevents larger system damage

❌ Disadvantages

- Short-term repair costs

- Downtime during service

Delaying repairs usually increases long-term expenses.

How Extreme Heat Affects Semi Truck AC Performance

High ambient temperatures put additional strain on AC systems.

Heat-Related Factors:

- Higher refrigerant pressure

- Reduced condenser efficiency

- Increased compressor workload

Regular maintenance is essential for hot-weather operations.

Preventive Maintenance Tips for Semi Truck AC Systems

Best Practices:

- Inspect AC annually

- Clean condenser every 3–6 months

- Replace cabin filters regularly

- Run AC weekly, even in winter

These steps extend system life and maintain cooling efficiency.

Real-World Case Example

A long-haul driver reported weak cooling during summer runs. Diagnosis revealed:

- Low refrigerant

- Minor hose leak

Repair cost: $280

Result: Full cooling restored and fuel efficiency improved due to reduced engine load.

Does a Semi Truck AC Affect Fuel Efficiency?

Yes—but minimally.

A properly functioning AC system increases fuel use by 3–5%, while a failing system can cause higher engine strain and inefficiency.

FAQ: Semi Truck AC Not Blowing Cold Air

Q1: Why does my semi truck AC blow warm air only when idling?

This often indicates low refrigerant, weak condenser airflow, or a failing fan clutch.

Q2: How long should a semi truck AC compressor last?

Typically 8–12 years, depending on usage and maintenance.

Q3: Can I drive with a broken AC compressor?

Yes, but it’s not recommended due to comfort, safety, and potential engine strain.

Q4: How often should refrigerant be recharged?

Only when levels drop—AC systems are sealed and should not need regular recharging.

Q5: Is AC repair tax-deductible for owner-operators?

Often yes, as a business expense—consult a tax professional.

Conclusion

If your semi truck AC not blowing cold air, the issue is usually fixable with proper diagnosis. From low refrigerant to compressor failure, addressing the problem early saves money and keeps you comfortable on the road.

If this guide helped you, share it on social media to help other drivers stay cool and safe during their hauls 🚛❄️

Leave a Reply