A Service Truck PTO Air Compressor is an essential component for service trucks used in construction, utilities, and fleet maintenance. These compressors are powered by the truck’s power take-off (PTO) system, providing reliable air pressure for pneumatic tools, tire inflation, and other air-powered applications. Understanding how a Service Truck PTO Air Compressor works, its maintenance requirements, and benefits can save time, improve efficiency, and extend the life of your equipment.

What is a Service Truck PTO Air Compressor?

A Service Truck PTO Air Compressor is an air compressor that draws power from the truck’s engine via the PTO system. Unlike electric or standalone compressors, PTO compressors use the mechanical energy of the truck to generate air pressure. This setup is particularly advantageous for service trucks that require high airflow and sustained pressure for extended periods.

Read too: Franklin Truck Parts Near Me: Your Complete Guide to Local Truck Parts & Repair Solutions

Common applications include:

- Inflating tires on trucks, trailers, and heavy equipment

- Operating pneumatic tools like impact wrenches, drills, and grinders

- Powering air suspension systems

- Supporting cleaning and maintenance operations with air-powered equipment

How a Service Truck PTO Air Compressor Works

The Service Truck PTO Air Compressor operates through the truck’s PTO, which transfers engine power to the compressor. The basic process involves:

- Engaging the PTO: The driver activates the PTO via a switch or lever, connecting the engine to the compressor.

- Air Compression: The compressor draws in air and pressurizes it using pistons or rotary mechanisms.

- Air Storage: Compressed air is stored in onboard tanks, ready for use.

- Distribution: Air is delivered through hoses to tools, equipment, or tire systems as needed.

This method ensures a continuous air supply without draining the truck’s electrical system, making it ideal for heavy-duty service operations.

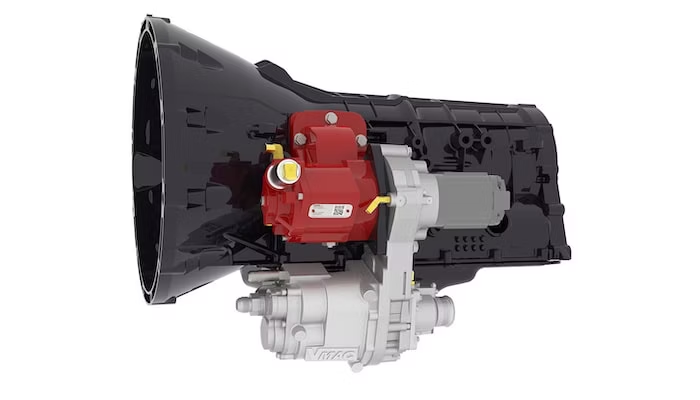

Components of a Service Truck PTO Air Compressor

Understanding the components helps operators maintain efficiency and prevent downtime. Key components include:

- Compressor Pump: Converts engine power into compressed air.

- Air Storage Tank: Stores pressurized air for consistent delivery.

- PTO Drive Unit: Transfers engine power to the compressor.

- Control System: Manages engagement, pressure levels, and safety features.

- Air Filters: Keep the system free of dust and contaminants.

- Hoses and Fittings: Ensure proper air delivery to tools and equipment.

Benefits of Using a Service Truck PTO Air Compressor

Investing in a Service Truck PTO Air Compressor provides several advantages:

1. High Air Output

PTO compressors deliver higher airflow and pressure than portable or electric alternatives, making them suitable for heavy-duty applications.

2. Continuous Operation

Unlike battery-powered compressors, PTO units can operate continuously as long as the truck engine is running, supporting long work shifts without overheating.

3. Fuel Efficiency

By using the truck engine’s power, PTO compressors reduce reliance on separate fuel sources or electricity, which can lower operational costs.

4. Versatility

A PTO air compressor can power a wide range of pneumatic tools, inflators, and equipment, increasing the truck’s utility in field operations.

5. Durability and Reliability

PTO compressors are built for commercial and industrial use, designed to withstand rugged environments and frequent operation.

Installation of a Service Truck PTO Air Compressor

Proper installation is crucial for safe and efficient operation. Key steps include:

- Select the Right PTO Compressor: Consider airflow requirements, truck engine compatibility, and intended applications.

- Mount the Compressor: Install securely on the truck frame or service body.

- Connect the PTO Drive: Link the compressor to the truck engine using the PTO system.

- Install Air Tanks and Hoses: Ensure proper storage and distribution of compressed air.

- Connect Control Systems: Integrate switches, gauges, and safety valves for easy operation.

- Test the System: Verify proper airflow, pressure levels, and functionality of all safety features.

Professional installation is recommended to ensure proper alignment, secure mounting, and system longevity.

Maintenance Tips for Service Truck PTO Air Compressors

Regular maintenance is essential to maximize efficiency and prevent breakdowns. Best practices include:

- Check Oil Levels: For lubricated compressors, ensure adequate oil levels for smooth operation.

- Inspect Hoses and Fittings: Replace damaged hoses or worn fittings to prevent leaks.

- Clean Air Filters: Keep intake filters free of dust and debris to maintain air quality.

- Drain Air Tanks: Remove accumulated moisture to prevent rust and corrosion.

- Test Safety Valves: Ensure pressure relief valves are functioning correctly to avoid overpressure hazards.

- Monitor PTO Engagement: Check for smooth engagement and disengagement to prevent wear on the PTO and compressor.

Common Issues and Troubleshooting

Even durable PTO air compressors may face issues if not properly maintained:

- Low Air Pressure: Often caused by leaks, worn valves, or clogged filters.

- Excessive Noise: Can indicate worn bearings or misalignment in the PTO drive.

- Overheating: Continuous operation without proper lubrication or airflow can cause heat buildup.

- PTO Engagement Problems: Improper installation or linkage issues can prevent the compressor from engaging correctly.

Addressing these issues promptly ensures uninterrupted operation and prevents costly repairs.

Best Practices for Safe Operation

To ensure safety and efficiency when using a Service Truck PTO Air Compressor, operators should:

- Wear PPE: Gloves, safety glasses, and hearing protection when operating pneumatic tools.

- Check Pressure Ratings: Do not exceed the compressor’s maximum pressure specifications.

- Use Approved Hoses and Fittings: Ensure all connections can handle the system’s airflow and pressure.

- Avoid Contamination: Prevent dirt or debris from entering the compressor or air tools.

- Follow Manufacturer Guidelines: Adhere to operational procedures and maintenance schedules.

Choosing the Right Service Truck PTO Air Compressor

Selecting the right system depends on several factors:

- Truck Compatibility: Ensure PTO system and engine power are sufficient to drive the compressor.

- Airflow Requirements: Match CFM (cubic feet per minute) to tool and application needs.

- Tank Capacity: Larger tanks provide longer operation without pressure drops.

- Durability: Consider materials and design for rugged field conditions.

- Budget and ROI: Balance initial investment with long-term operational savings.

Conclusion

A Service Truck PTO Air Compressor is a powerful, reliable, and versatile tool for service truck operations. It provides continuous airflow for pneumatic tools, tire inflation, and maintenance tasks while leveraging the truck’s engine power. Proper installation, routine maintenance, and adherence to safety best practices ensure long-term performance and cost savings.

For fleet operators and technicians, investing in a PTO air compressor enhances operational efficiency, reduces downtime, and increases the overall utility of service trucks. Understanding the system’s components, maintenance needs, and safe operation is essential for maximizing performance and prolonging service life.

Leave a Reply