If you’ve noticed your truck air bags not inflating, you’re not alone. Many truck owners face this frustrating issue, especially when their suspension system starts sagging or their ride feels rough. Air suspension is essential for maintaining stability, load leveling, and comfort — so when it fails, it’s more than just an inconvenience.

This article explains the most common causes, how to diagnose and repair the problem, and prevent future air suspension issues — written for truck owners who want clear, reliable guidance.

Read too: Franklin Truck Parts Near Me: Your Complete Guide to Local Truck Parts & Repair Solutions

Understanding Truck Air Suspension Systems

A truck’s air suspension system replaces traditional steel springs with air-filled bags (also called air springs) that adjust based on weight and road conditions. When working properly, they:

- Maintain consistent ride height regardless of load.

- Improve ride comfort by absorbing shocks.

- Help with load balancing and tire longevity.

- Enhance fuel efficiency through better aerodynamics.

When the system fails to inflate properly, your truck might:

- Sit lower than normal, especially in the rear.

- Trigger a suspension warning light.

- Feel unstable or bounce excessively while driving.

Why Are My Truck Air Bags Not Inflating? (Top 5 Causes)

1. Air Leaks in the System

The most common culprit is air leaks in the air lines, fittings, or the bags themselves. Over time, rubber bags can dry out or crack.

How to check:

- Spray soapy water on fittings and hoses.

- Look for bubbles forming — this indicates a leak.

Expert Tip: Even a small pinhole can cause the system to deflate overnight. Replacing worn-out hoses or bags can restore function quickly.

2. Faulty Air Compressor

The air compressor pumps air into the bags. If it fails, the system won’t pressurize properly.

Symptoms:

- You don’t hear the compressor running.

- The truck doesn’t rise even after starting.

Checkpoints:

- Test the power supply and fuse.

- Listen for unusual noises like grinding or clicking.

If the compressor is dead, replacement costs range from $250–$700, depending on the model.

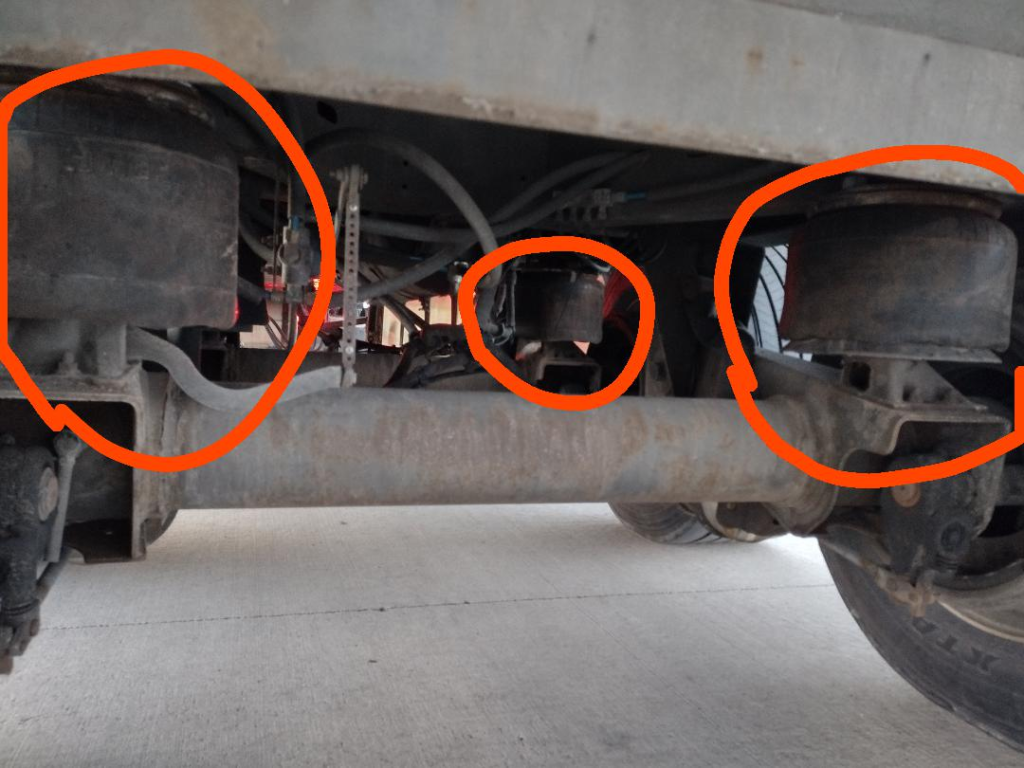

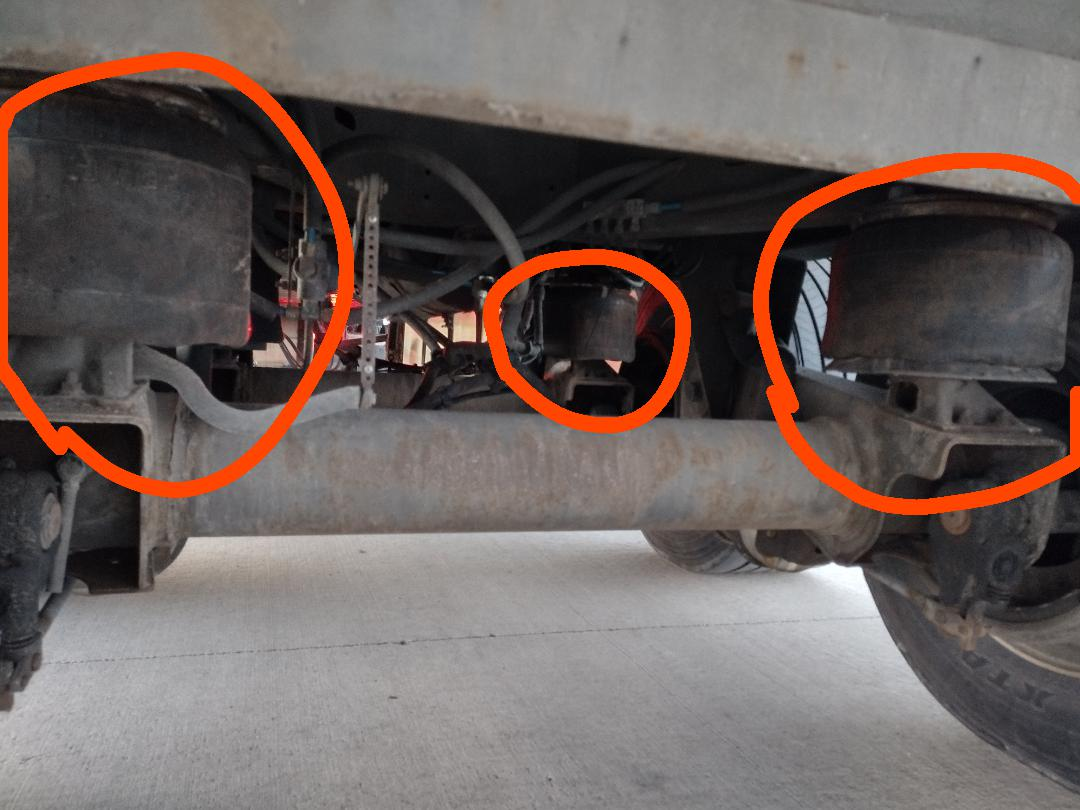

3. Damaged Air Bags (Air Springs)

Even minor cracks or punctures in the air bags can prevent inflation.

Look for:

- Cracks around folds.

- Dry rot or visible air leaks.

Solution:

Replace damaged air springs. Quality replacements (like Firestone or Air Lift) cost around $100–$300 per bag but can last 5–7 years with proper care.

4. Electrical or Sensor Malfunctions

Modern air suspension systems rely on height sensors, relays, and control modules. If any of these components fail, the system won’t inflate correctly.

Check:

- Height sensor connections near the axle.

- Fuses and relays in the suspension control circuit.

A bad height sensor may send false readings, tricking the system into thinking the bags are already full.

5. Blocked or Frozen Air Lines

Dirt, ice, or moisture in air lines can block airflow. This is common in cold or humid environments.

Fix:

- Drain the air dryer regularly.

- Use compressed air to blow out the lines.

- In winter, park the truck in a heated garage if possible.

Step-by-Step: How to Fix Truck Air Bags Not Inflating

1. Inspect and Test the System

Start with a visual inspection:

- Check if the air bags are flat or uneven.

- Listen for hissing sounds (leaks).

- Verify if the compressor activates when the ignition is on.

2. Locate Leaks

Spray a mix of soap and water along the air lines and fittings. Bubbles will reveal leaks.

- Tighten loose fittings.

- Replace cracked hoses.

3. Check Power to the Compressor

Use a multimeter:

- Voltage should read 12V–14V when the ignition is on.

- If there’s no power, inspect relays, fuses, and wiring.

4. Test the Height Sensor

The sensor tells the system when to inflate or deflate the bags.

- Manually move the sensor arm and listen for compressor activation.

- If there’s no response, the sensor may need replacing.

5. Replace Damaged Air Bags

If leaks are in the bags:

- Jack up the truck safely.

- Depressurize the air system.

- Disconnect the old air spring.

- Install the new one, following manufacturer torque specs.

- Refill and test for leaks.

6. Reset the Suspension System

After repairs, reset the suspension control module (varies by model). Some trucks require a diagnostic scan tool to clear error codes.

Air Suspension vs. Coil Springs – Comparison

| Feature | Air Suspension | Coil Springs |

|---|---|---|

| Comfort | Excellent | Moderate |

| Load Leveling | Automatic | Manual (requires helper springs) |

| Maintenance | High | Low |

| Cost | Expensive | Affordable |

| Durability | 5–7 years (with care) | 10+ years |

While air suspension offers superior comfort and leveling, it requires more maintenance and timely inspections to prevent costly repairs.

Preventive Maintenance Tips

Keeping your truck’s air suspension in shape is easier than dealing with major repairs. Here’s how:

- Inspect monthly for visible cracks or air leaks.

- Clean and lubricate fittings every 6 months.

- Replace air dryer filters annually to remove moisture.

- Avoid overloading your truck — it stresses the suspension.

- Listen for unusual noises after startup (compressor cycling too often indicates leaks).

According to Wikipedia, regular maintenance can extend air suspension lifespan by over 50% and improve vehicle handling.

Safety Risks of Driving with Deflated Air Bags

Driving with air bags that don’t inflate properly can cause:

- Uneven tire wear

- Poor handling and stability

- Brake system stress

- Frame or axle damage

If your truck sags on one side or feels unstable, it’s best to avoid long trips until the issue is fixed.

FAQ – Truck Air Bags Not Inflating

1. Can I drive my truck if the air bags aren’t inflating?

It’s possible for short distances, but not recommended. Continuous driving can cause tire, axle, and brake damage.

2. How do I know if my compressor is bad?

If the compressor doesn’t start, makes grinding noises, or runs constantly without raising the truck, it’s likely faulty.

3. How long do truck air bags last?

Typically 5–7 years, depending on usage and exposure to heat or road salt.

4. How much does it cost to replace air suspension?

Average costs range from $500–$2,000, depending on parts and labor.

5. Why does my air suspension deflate overnight?

Tiny leaks in fittings or air lines allow air to escape slowly. Use soapy water to identify and seal them.

6. Do I need to replace both air bags at once?

It’s highly recommended. If one has failed, the other is likely worn too. Replacing both ensures balanced performance.

Conclusion

A truck air suspension system is vital for ride comfort and stability, especially under heavy loads. When your truck air bags stop inflating, the problem could stem from a simple air leak — or a more complex compressor or sensor failure.

By following the steps above, you can diagnose the issue accurately and fix it safely. Regular maintenance will save you hundreds in repairs and keep your truck performing at its best.

Leave a Reply