If your truck’s air compressor keeps running nonstop or the air brakes don’t release properly, the problem might lie in the Unloader Valve Truck Air Compressor. This small but essential component plays a big role in maintaining the air pressure your truck relies on for safe braking and operation.

In this guide, we’ll explain exactly what the unloader valve does, how it works, the signs of a failing valve, and how to replace or maintain it — step by step. Whether you’re a fleet owner or a solo truck operator, understanding this part can save you downtime, repair costs, and potential accidents.

Read too: Top Trucking Companies That Still Have Manual Transmissions

What Is an Unloader Valve in a Truck Air Compressor?

The unloader valve is a pressure control device installed on the air compressor system of heavy-duty trucks. Its main job is to release trapped air pressure from the compressor head and lines when the compressor reaches its cut-out pressure.

This allows the compressor to restart easily and prevents excessive strain on the motor.

In simple terms:

The unloader valve tells the compressor when to rest and when to work — keeping your air system balanced and efficient.

How Does the Unloader Valve Work?

The Unloader Valve Truck Air Compressor operates alongside the governor. When system pressure reaches the maximum level (usually around 120–130 PSI), the governor signals the unloader valve to open and bleed off air pressure from the compressor head.

When pressure drops back to the minimum level (around 100 PSI), the governor signals the unloader to close, allowing the compressor to build air pressure again.

Step-by-Step Process:

- Compressor builds air to system pressure (up to 120–130 PSI).

- Governor detects full pressure and triggers the unloader valve.

- Unloader valve opens, releasing air and unloading the compressor.

- Air system consumes air and pressure drops.

- Governor resets and closes the unloader valve to rebuild pressure.

This cycle ensures smooth, controlled operation — preventing compressor overwork and air system damage.

Why Is the Unloader Valve Important?

A properly working unloader valve ensures:

- ✅ Stable air pressure for brakes and accessories

- ✅ Reduced compressor wear and tear

- ✅ Lower risk of overheating

- ✅ Improved fuel efficiency

- ✅ Faster compressor restart times

Without it, your truck’s compressor could be forced to work continuously — leading to premature failure or even air brake malfunction, which can be extremely dangerous on the road.

Symptoms of a Bad Unloader Valve

If your unloader valve is faulty, your truck will often tell you. Here are the most common signs:

| Symptom | Possible Cause |

|---|---|

| Constant air compressor cycling | Valve stuck open or governor issue |

| Air pressure buildup too slow | Valve leaking or dirty |

| Air leaking after compressor shuts off | Valve not sealing properly |

| Loud hissing noise near compressor | Faulty or cracked unloader valve |

| Compressor won’t unload | Valve jammed or air line blocked |

💡 A slow pressure buildup can also indicate a failing check valve or moisture in the air lines — check both before replacing parts unnecessarily.

How to Test a Truck Air Compressor Unloader Valve

You can test your unloader valve with a simple visual and pressure check.

Here’s how:

- Start your truck and let the air compressor build pressure to full (around 120 PSI).

- Listen carefully — when the compressor cuts out, you should hear a brief hiss as the unloader releases air.

- If you don’t hear a hiss or the compressor continues running, your unloader valve may be stuck or malfunctioning.

- Spray soapy water on the valve and lines to check for air leaks. Bubbles mean a leak.

How to Replace a Truck Air Compressor Unloader Valve (Step-by-Step)

If testing confirms your valve is bad, here’s how to replace it safely.

Tools You’ll Need:

- Wrench set

- Screwdriver

- Replacement unloader valve (OEM recommended)

- Thread sealant or Teflon tape

- Safety gloves and goggles

Step 1: Release Air Pressure

Turn off the engine and drain the air tanks completely to avoid injury.

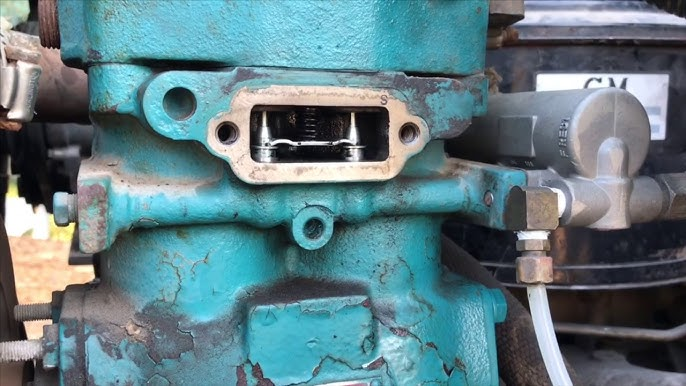

Step 2: Locate the Unloader Valve

Find it near the air compressor or integrated into the governor assembly.

Step 3: Disconnect the Old Valve

Remove the airline fittings and unbolt the valve carefully.

Step 4: Install the New Valve

Apply thread sealant and tighten the new valve securely.

Step 5: Reconnect and Test

Reattach the airline, restart your engine, and check for proper operation. Listen for the unload hiss when the system reaches full pressure.

Note: Always refer to your truck’s service manual for torque specifications and valve model compatibility.

Maintenance Tips for Longevity

Keeping your truck air compressor unloader valve in top condition isn’t complicated. Here are some practical tips:

- 🧰 Clean regularly: Dirt and oil buildup can cause valve sticking.

- 💧 Drain air tanks daily to remove moisture and prevent corrosion.

- 🔍 Inspect the governor — many “valve problems” are actually governor issues.

- 🔄 Replace air filters on schedule to prevent debris from entering the system.

- 📅 Test system pressure monthly to ensure consistent cutoff and restart cycles.

Unloader Valve vs Check Valve: What’s the Difference?

| Feature | Unloader Valve | Check Valve |

|---|---|---|

| Function | Releases pressure to unload compressor | Prevents air from flowing back into compressor |

| Location | Near compressor head or governor | Between compressor and air tank |

| Operates When | System reaches cut-out pressure | Constantly |

| Failure Symptoms | Compressor runs constantly | Air leaks back to compressor |

These two parts often get confused, but they serve very different purposes. When troubleshooting, check both to avoid unnecessary part replacements.

People Also Ask

1. What causes an unloader valve to fail?

Dirt, oil contamination, worn seals, or faulty governor signals are common causes of unloader valve failure. Regular cleaning and maintenance prevent most issues.

2. Can I clean a stuck unloader valve instead of replacing it?

Yes, you can try cleaning it using compressed air and a small brush. If the valve is corroded or damaged, replacement is recommended.

3. How often should I replace the unloader valve?

Typically every 3–5 years, depending on mileage, air system condition, and maintenance practices.

4. Is it safe to drive with a bad unloader valve?

No. A faulty valve can cause the compressor to overwork or fail, potentially leading to air brake loss, which is a major safety risk.

5. How much does a replacement cost?

Most truck unloader valves cost between $40–$150, depending on brand and model. Labor adds about $100–$200 if done by a mechanic.

6. Where can I find the unloader valve on my truck?

Usually, it’s located on or near the air compressor, or integrated with the air governor assembly.

External Reference

For a detailed explanation of air compression systems, visit Wikipedia’s Air Compressor page.

Conclusion

Your Unloader Valve Truck Air Compressor may be small, but its role is critical in keeping your truck’s air brake system reliable and efficient.

By understanding how it works, recognizing failure signs early, and following proper maintenance, you’ll extend your compressor’s life, avoid costly downtime, and stay compliant with DOT safety standards.

Leave a Reply