If you drive or operate a heavy-duty truck, you already know how essential air systems are for your vehicle’s performance and reliability. Whether it’s powering air brakes, inflating tires, or running pneumatic tools, having a reliable engine driven air compressor for truck use is non-negotiable.

Choosing the right system can be challenging, with so many models, power ratings, and configurations available. This guide will help you understand how these compressors work, what to look for, and which models are best for your truck and your workload.

Read too: Franklin Truck Parts Near Me: Your Complete Guide to Local Truck Parts & Repair Solutions

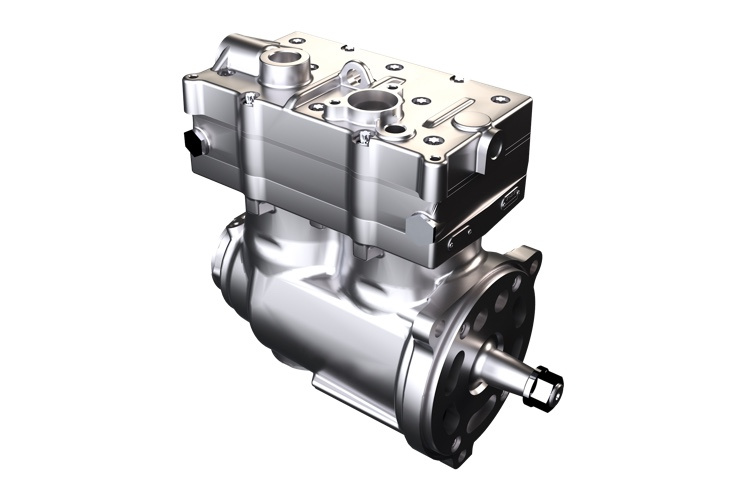

What Is an Engine Driven Air Compressor for Truck?

An engine driven air compressor is a type of compressor powered directly by the truck’s engine instead of an electric motor. These compressors provide continuous and high-volume airflow, making them ideal for large vehicles that depend on air systems for braking, suspension, and tools.

In simple terms, the compressor converts mechanical energy from the truck’s engine into pressurized air, which is then stored in tanks and distributed through the vehicle’s pneumatic system.

According to TruckersReport, over 90% of heavy-duty trucks in the U.S. rely on engine-driven compressors for essential air brake systems.

How Does an Engine Driven Air Compressor Work?

The process is simple but highly efficient. Here’s a step-by-step breakdown:

- Power Source: The compressor is belt-driven or gear-driven by the engine.

- Air Intake: Air enters the compressor through an intake filter.

- Compression Stage: Pistons or rotary elements compress the air.

- Cooling and Storage: Compressed air is cooled and stored in air tanks.

- Distribution: Air is used for brakes, suspension, or air-powered accessories.

This system ensures your truck always has a steady and dependable air supply even during extended hauls.

Benefits of Engine Driven Air Compressors

Here are the key reasons truck owners and fleet operators prefer engine-driven models:

- Continuous Power: Works whenever your engine runs—no waiting for batteries or charging.

- Heavy-Duty Capability: Handles large air volumes needed for braking and pneumatic systems.

- Durability: Designed for commercial-grade use in harsh environments.

- Low Maintenance: Minimal moving parts compared to standalone compressors.

- Energy Efficiency: Converts mechanical power directly, minimizing energy loss.

According to Fleet Equipment Magazine, engine-driven systems reduce overall downtime by up to 25% compared to external air systems.

Types of Engine Driven Air Compressors

Not all compressors are the same. Depending on your needs, you can choose among several designs:

1. Reciprocating (Piston) Compressors

These use pistons to compress air into storage tanks. They’re durable and great for high-pressure requirements.

Best for: Heavy-duty trucks and industrial applications.

Pros:

- Powerful compression

- Long lifespan

- Easy maintenance

Cons:

- Louder operation

- Heavier than rotary types

2. Rotary Screw Compressors

These compressors use twin rotors to compress air continuously. They’re quieter and provide steady airflow without pulsation.

Best for: Long-haul trucks or continuous-duty applications.

Pros:

- Quieter and smoother

- High air output

- Energy-efficient

Cons:

- Higher initial cost

- More complex repairs

3. Clutch-Driven Compressors

These systems engage or disengage via an electric clutch, saving fuel and reducing wear when air isn’t needed.

Best for: Trucks needing variable air demand or mixed-use operations.

Pros:

- Extends compressor life

- Reduces engine load

- Ideal for modern fleet optimization

Cons:

- Slightly more complex installation

Top Features to Look For in a Truck Air Compressor

When choosing an engine driven air compressor for your truck, consider these critical factors:

- Airflow (CFM): Determines how much air the compressor delivers.

- For air brakes: 10–13 CFM

- For tools: 15–25 CFM or more

- Pressure Rating (PSI): Heavy-duty systems need around 120–150 PSI.

- Duty Cycle: Choose at least a 100% duty cycle for continuous operation.

- Mounting Options: Frame-mounted or engine-mounted depending on space.

- Cooling System: Air or oil cooling for temperature control.

- Material: Cast iron and aluminum components increase durability.

- Brand Reputation: Go for trusted brands with proven performance and parts availability.

Best Engine Driven Air Compressors for Trucks (2025 Picks)

| Brand & Model | CFM Output | Max PSI | Type | Best For |

|---|---|---|---|---|

| VMAC UNDERHOOD40 | 40 CFM | 150 PSI | Rotary Screw | Mobile service trucks |

| Boss Bullet GSD | 30 CFM | 125 PSI | Reciprocating | Utility & towing trucks |

| Ingersoll Rand 2475N7.5 | 24 CFM | 175 PSI | Piston | Shop service & fleet use |

| Vanair Viper Gas Drive | 20–30 CFM | 150 PSI | Rotary Screw | Field repairs & maintenance |

Each of these compressors is built for reliability, portability, and heavy use, making them popular among truck operators across the U.S.

Installation Guide: Setting Up an Engine Driven Air Compressor

Step-by-Step Installation Process

- Choose Mounting Location: Secure the compressor near the truck’s engine bay or chassis frame.

- Attach Brackets: Use vibration-dampening mounts to prevent engine stress.

- Connect Belt or Gear Drive: Align the compressor drive with the engine pulley.

- Install Air Lines: Run hoses to the air tank and accessories.

- Wire the Clutch (if applicable): Connect the control switch to the ignition.

- Test System: Start the engine and check pressure build-up and leaks.

Pro Tip: Always ensure proper alignment between the compressor pulley and engine crankshaft to avoid premature wear.

For more details about air compression mechanics, you can read about the Air Compressor System on Wikipedia.

Maintenance Tips for Longevity

Keeping your engine driven air compressor in good condition ensures years of dependable service.

- Check Oil Levels weekly (if oil-lubricated).

- Inspect Belts and Hoses monthly for cracks or leaks.

- Drain Moisture Tanks daily to prevent corrosion.

- Replace Air Filters every 3–6 months.

- Monitor Pressure Gauges regularly to ensure safe operation.

Proper maintenance can extend compressor life by 40% or more, according to Fleet Maintenance Magazine.

Pros and Cons Comparison

| Advantages | Disadvantages |

|---|---|

| Continuous operation with engine | Increases engine load slightly |

| High airflow for heavy-duty tasks | Installation may require modification |

| Lower maintenance vs. electric compressors | Higher upfront cost |

| Compact and efficient | Noise at high RPM |

Common Applications

An engine driven air compressor for truck isn’t just for air brakes. It’s a versatile tool for multiple on-road and job-site applications:

- Air suspension systems

- Tire inflation

- Pneumatic tools (impact wrenches, drills)

- Sandblasting and painting

- Industrial and construction support

Fleet operators often rely on these compressors for mobile maintenance units, ensuring constant power in remote areas without electricity.

Frequently Asked Questions (FAQ)

1. What size engine driven air compressor do I need for my truck?

It depends on your usage. For air brakes and light tools, 10–15 CFM is sufficient. For heavy-duty operations, go for 20–40 CFM.

2. Can I install an engine driven compressor myself?

If you have mechanical experience, yes. Otherwise, it’s best to hire a professional installer for alignment and safety checks.

3. How often should I service my compressor?

Perform oil and filter changes every 500–700 hours of use or as recommended by the manufacturer.

4. Are these compressors fuel-efficient?

Yes, modern systems use clutches and smart drive designs to minimize engine load, improving fuel efficiency by up to 10%.

5. Can I use a gasoline-powered compressor instead?

Yes, but engine-driven systems are more efficient for trucks because they use the vehicle’s existing power source.

6. What’s the average cost?

Prices range from $1,500 to $6,000, depending on size, type, and brand.

Conclusion

A high-quality engine driven air compressor for truck is one of the smartest upgrades you can make for performance, safety, and efficiency. Whether you operate a heavy-duty fleet, a service truck, or a mobile repair unit, the right compressor ensures consistent air power wherever you go.

Brands like VMAC, Vanair, and Boss lead the market with reliable systems built for long-term durability and efficiency. Invest wisely, maintain regularly, and your compressor will deliver years of dependable service on the road.

Leave a Reply