Heavy duty trucks are complex machines, relying on intricate electrical systems to power everything from lights and sensors to engine control modules and safety systems. To maintain, repair, or upgrade these vehicles effectively, understanding Heavy Duty Truck Wiring Diagrams is essential.

Whether you’re a professional mechanic, a fleet maintenance technician, or a truck enthusiast, this guide will help you decode wiring diagrams, identify components, and troubleshoot problems faster.

Read too: Box Truck Roll Up Door Replacement: Costs, Process, and What You Need to Know

Why Wiring Diagrams Matter for Heavy Duty Trucks

Electrical issues are among the most common problems in heavy duty trucks. A wiring diagram acts as a roadmap for the truck’s electrical system, showing how every wire, connector, fuse, and component is linked.

Key reasons to use wiring diagrams include:

- Accurate troubleshooting – Identify where a circuit begins and ends.

- Safe repairs – Prevent accidental shorts or incorrect connections.

- Faster diagnostics – Reduce time spent guessing about wiring paths.

- Preventing costly damage – Avoid frying control modules or sensors.

Heavy Duty Truck Wiring Diagrams – What They Show

A wiring diagram for a heavy duty truck typically includes:

- Power sources – Battery, alternator, and auxiliary power systems.

- Ground points – Essential for completing electrical circuits.

- Wiring harness layouts – Grouped wires running to various systems.

- Connectors and terminals – Physical joining points between wires.

- Fuses, breakers, and relays – Protection devices for circuits.

- Component locations – Lights, sensors, motors, controllers, and more.

These diagrams can be schematic (showing connections in symbolic form) or layout diagrams (showing physical routing).

Types of Heavy Duty Truck Wiring Diagrams

There are several types of diagrams you may encounter:

1. Schematic Diagrams

These show the electrical flow in symbolic form. Great for diagnosing wiring faults.

2. Harness Layout Diagrams

Show the physical routing of wires, including their grouping into harnesses and connection points.

3. Component Location Diagrams

Highlight where each part is installed in the truck, helping with physical inspections.

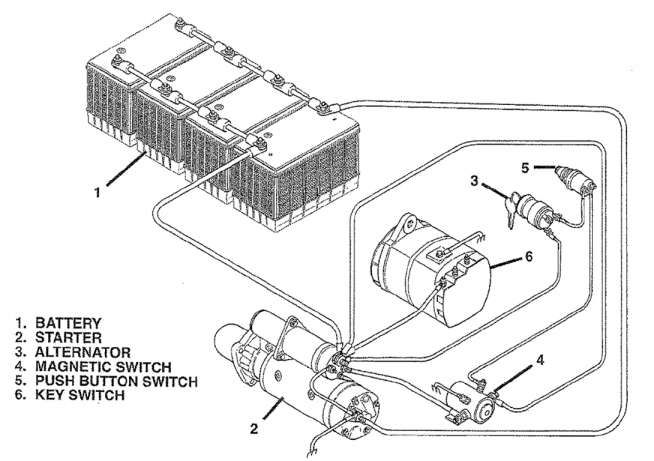

4. Pictorial Diagrams

Use images instead of symbols, often found in training manuals.

How to Read Heavy Duty Truck Wiring Diagrams

Reading a wiring diagram effectively requires understanding its structure and symbols.

Step 1: Identify the Legend and Symbols

Every wiring diagram comes with a legend that explains what each symbol represents — such as switches, lights, grounds, and fuses.

Step 2: Follow the Power Flow

Start at the battery or main power source and trace how electricity travels through the system.

Step 3: Locate the Component

Find the component in question on the diagram and trace back through its power and ground paths.

Step 4: Note Color Codes

Wires are usually color-coded, such as:

- BLK – Black (ground)

- RED – Power supply

- YEL/BLK – Yellow with black stripe (specific circuit)

Step 5: Check Connectors and Splices

These are critical points where multiple wires join or branch off.

Troubleshooting with Heavy Duty Truck Wiring Diagrams

When an electrical problem occurs, a wiring diagram can guide your diagnostic process.

Example Scenario: Headlights Not Working

- Check the fuse for the headlight circuit.

- Use the diagram to find the headlight switch connection.

- Trace wiring to see if there’s a break, short, or bad ground.

- Inspect connectors along the circuit path.

Tips for Effective Troubleshooting:

- Always test circuits with a multimeter or test light.

- Verify both power and ground continuity.

- Never replace parts before confirming the cause.

Common Electrical Issues in Heavy Duty Trucks

- Corroded connectors – Often caused by exposure to moisture and road salts.

- Worn wiring insulation – Can lead to shorts or open circuits.

- Overloaded circuits – Causing blown fuses or melted wiring.

- Loose grounds – One of the most common culprits for intermittent failures.

Using Heavy Duty Truck Wiring Diagrams helps pinpoint these issues quickly.

Safety Tips When Working with Truck Wiring

- Disconnect the battery before working on electrical systems.

- Use insulated tools to prevent accidental shorts.

- Never bypass fuses or circuit breakers.

- Follow the manufacturer’s torque specs for electrical terminals.

Where to Find Heavy Duty Truck Wiring Diagrams

- Manufacturer service manuals – The most accurate and up-to-date.

- Online repair databases – Such as Mitchell1 or ALLDATA.

- Training materials – For those learning electrical diagnostics.

- OEM dealer resources – Often available for fleets and professional shops.

Upgrades and Modifications

When adding accessories or modifying systems, wiring diagrams are critical to ensure:

- Circuits are not overloaded.

- Proper fusing is used.

- Wiring is routed safely away from heat and moving parts.

For example, installing additional work lights on a heavy duty truck requires tapping into an auxiliary circuit or adding a dedicated fused circuit.

Digital vs. Paper Wiring Diagrams

Digital Advantages:

- Zoom in for detail.

- Search for specific terms.

- Link to component locations.

Paper Advantages:

- No device needed in the workshop.

- Can be marked with notes and highlights.

Many technicians prefer to keep both versions handy.

Best Practices for Using Heavy Duty Truck Wiring Diagrams

- Keep diagrams organized for each truck in the fleet.

- Mark any changes or repairs on the diagram.

- Train all technicians to read and interpret diagrams accurately.

- Combine diagram reading with live circuit testing for best results.

Conclusion

Understanding Heavy Duty Truck Wiring Diagrams is a critical skill for anyone maintaining or repairing these vehicles. Wiring diagrams are more than just lines and symbols — they are the blueprint to a truck’s electrical system.

By learning to read them correctly, you’ll diagnose problems faster, perform safer repairs, and extend the life of every component. Whether you’re working on a single truck or managing a fleet, mastering wiring diagrams is an investment in efficiency and reliability.

Leave a Reply