For truck drivers, fleet managers, and logistics companies, weight compliance is more than just a requirement—it’s essential for safety, efficiency, and profitability. Overloaded trucks not only risk costly fines but also cause premature wear on suspension systems, brakes, and tires. One of the most effective tools to combat this issue is the use of on board truck scales for spring suspension.

These scales are designed specifically for trucks with spring suspension systems, providing accurate real-time weight readings that help drivers stay within legal load limits. Whether you operate a single truck or manage an entire fleet, understanding how these systems work and why they matter can save you money, protect your equipment, and keep your business compliant with regulations.

Read too: Craigslist Cars And Trucks – By Owner: Tips, Risks, and How to Get the Best Deals

In this article, we’ll explore everything you need to know about on board truck scales for spring suspension, including their benefits, functionality, installation process, and how they compare to other weighing methods.

Why On Board Truck Scales Are Essential

The trucking industry is heavily regulated, and one of the biggest compliance concerns is weight management. Exceeding gross vehicle weight ratings (GVWR) or axle weight limits can result in:

- Fines and Penalties: Weigh station violations can lead to expensive fines.

- Vehicle Damage: Overloading puts additional stress on suspension systems, especially spring suspensions.

- Safety Risks: Excessive weight increases stopping distances, reduces stability, and raises the risk of accidents.

- Operational Delays: Being pulled over for weight violations means lost time and missed delivery schedules.

On board truck scales address these issues by giving drivers precise, real-time weight data. Instead of guessing or relying solely on external scales, drivers know exactly how much weight they’re carrying at all times.

On Board Truck Scales For Spring Suspension: How They Work

Unlike air suspension systems, which use air pressure sensors for weight measurement, on board truck scales for spring suspension use strain gauges and deflection measurements to calculate load weight.

Key Components Include:

- Load Sensors: Attached to the truck’s axles or suspension points, these sensors measure deflection caused by weight.

- Digital Display Unit: Located inside the cab, this screen provides real-time weight readings for gross and axle loads.

- Wiring & Control Modules: These connect the sensors to the display, ensuring accurate data transmission.

The system calculates weight by measuring how much the suspension compresses under load. Because spring suspensions behave predictably under pressure, this method is both reliable and consistent.

Benefits of Using On Board Truck Scales For Spring Suspension

- Accurate Weight Readings

Modern systems provide accuracy within a few hundred pounds, more than enough to ensure compliance. - Time Savings

Drivers can check weight instantly without needing to visit a certified weigh station unless required. - Cost Efficiency

Avoiding fines, reducing equipment wear, and minimizing fuel waste saves significant money over time. - Increased Safety

Prevents overloading that can lead to mechanical failures and accidents. - Driver Convenience

Easy-to-read displays keep drivers informed without requiring complex equipment. - Fleet Management Advantage

For companies, having on board scales helps standardize loading practices and ensures every truck leaves the yard compliant.

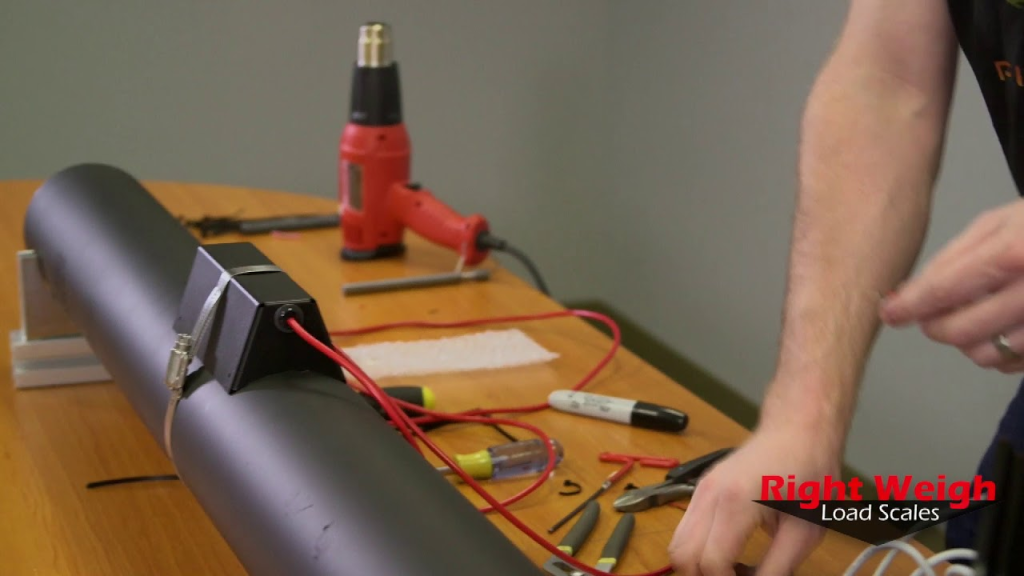

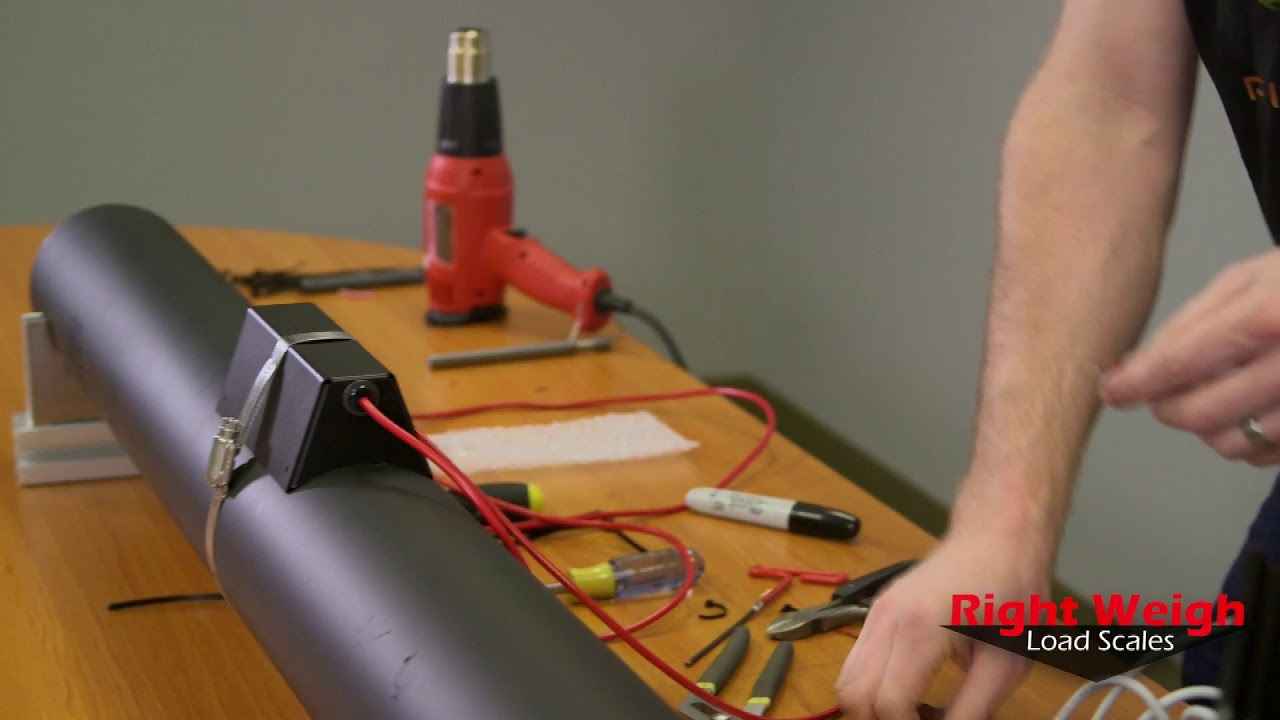

Installation of On Board Truck Scales

Installing on board truck scales for spring suspension is relatively straightforward, but it’s usually best handled by professionals to ensure calibration accuracy.

General Steps:

- Mount Sensors: Strain gauges are installed on axles or suspension points.

- Run Wiring: Cables are connected to a control unit and display monitor.

- Calibration: The truck is loaded to known weights to calibrate the system.

- Testing: Verification ensures the readings match actual load weights.

The installation process varies depending on the truck model and the brand of the on board scale, but most systems are designed to integrate seamlessly with spring suspensions.

Comparing Spring Suspension and Air Suspension Scales

- Air Suspension Scales: Use air pressure sensors, making them easier to calibrate and often more precise for heavy-duty trucks with full air systems.

- Spring Suspension Scales: Designed specifically for trucks with mechanical spring systems, these scales provide comparable accuracy but require strain-based sensors.

If your truck uses spring suspension, you need a dedicated system built for that setup—air suspension scales won’t work.

Legal Compliance and Regulations

DOT regulations require trucks to comply with federal and state weight limits. By using on board truck scales for spring suspension, drivers can:

- Ensure compliance before hitting weigh stations.

- Reduce the risk of being cited for overloading.

- Avoid out-of-service orders that can sideline a truck for hours or even days.

Costs and ROI of On Board Truck Scales

The price of on board truck scales for spring suspension can range from $1,000 to $3,500 per truck, depending on brand, features, and installation complexity. While the upfront cost may seem high, the return on investment is significant when you consider:

- Avoided fines (which can be thousands of dollars per incident)

- Reduced fuel costs by avoiding overweight inefficiencies

- Lower maintenance and repair bills due to reduced wear and tear

- Higher productivity from fewer weigh station delays

Choosing the Right On Board Scale System

When selecting an on board scale system, consider the following:

- Compatibility: Ensure the system is designed specifically for spring suspension.

- Accuracy: Look for systems with proven reliability and strong customer reviews.

- Ease of Use: Displays should be simple and easy to read while driving.

- Durability: Trucking environments are harsh—choose rugged systems built for heavy use.

- Support & Warranty: Reliable manufacturers offer strong customer service and extended warranties.

On Board Truck Scales For Spring Suspension in Everyday Operations

For many fleets, these systems become essential tools. Truck drivers hauling aggregate, construction materials, agriculture loads, or other heavy commodities benefit most because weight often fluctuates with every load.

Instead of guessing, drivers know the exact weight before leaving a site, ensuring loads are within legal and safe limits. Fleet managers can also monitor compliance more effectively, reducing risk across multiple vehicles.

Future of On Board Weighing Technology

The future of on board truck scales for spring suspension is moving toward:

- Wireless Systems: Bluetooth and Wi-Fi enabled displays that transmit data to mobile devices.

- Telematics Integration: Fleet managers can monitor weight remotely in real time.

- Increased Accuracy: Advances in sensor technology are pushing accuracy to within 1% of actual weight.

- AI-Based Load Prediction: Some systems may eventually predict optimal load distribution for safety and efficiency.

Frequently Asked Questions

1. Are on board truck scales legal for weight enforcement?

No. They are not certified by DOT weigh stations but are used as preventive tools to ensure compliance before roadside checks.

2. Can they be transferred between trucks?

Yes, but removal and reinstallation require calibration, making it more practical to dedicate them to specific vehicles.

3. Do they work on trailers?

Yes, many systems can be installed on trailers with spring suspension.

4. How often should they be calibrated?

Calibration should be checked annually or whenever major suspension repairs are made.

Final Thoughts

On board truck scales for spring suspension are a powerful solution for drivers and fleets looking to stay compliant, protect equipment, and maximize efficiency. By providing real-time weight data, they help prevent costly fines, improve safety, and streamline operations.

For small trucking businesses and large fleets alike, investing in these systems isn’t just about compliance—it’s about building smarter, more cost-effective operations in today’s competitive trucking industry.

Leave a Reply